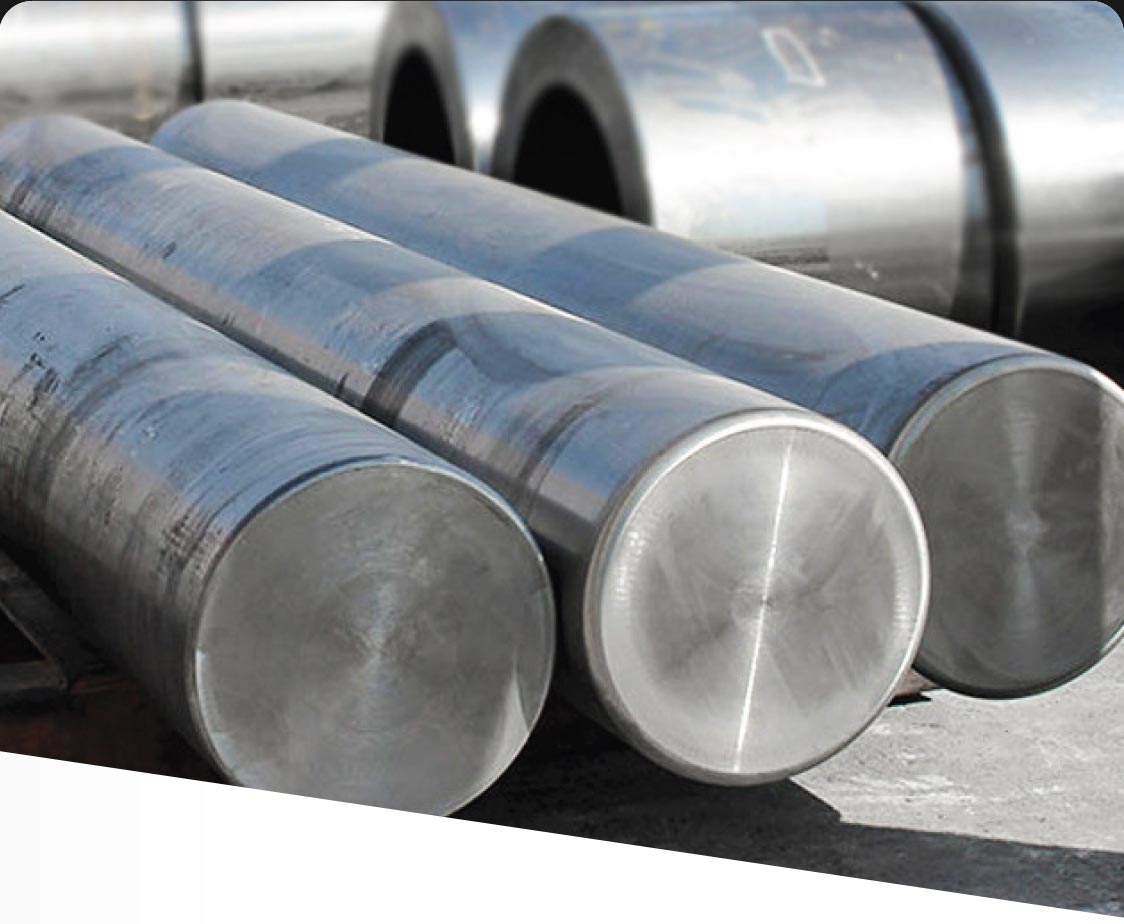

Using A182 F1 material for round bars is one of the best ways to use alloy steel in construction projects. This material has a lot of advantages, including its strength, quality, and cost-effectiveness. The most commonly used alloy steels are A182 F1 (22% Chromium, 5% Nickel) and 2507 (25 percent Chromium, seven percent Nickel). These are used in various applications, including oil and gas, pulp and paper, and chemical specialty. These are low-alloy steels that have outstanding performance. These A182 F1 Material alloys also have excellent corrosion resistance and high strength. In addition, they are used in heat transfer process equipment and the petrochemical industry. They are also widely used in pharmaceutical applications.

Corrosion resistance of A182 F1 Alloy Steel Round Bars

Alloy steel is a corrosion-resistant material that is used for several applications. It is used in architecture, plumbing, and medicine. Moreover, its strength and durability are critical. These properties make it useful for high-temperature applications. Alloy steel is also a highly corrosion-resistant material. It is composed of nickel, iron, and chromium. The chromium content is very high, which helps resist scaling at elevated temperatures. This alloy is used in aerospace, chemical processing, and pharmaceuticals. A182 F1 Material Alloy steel round bars are manufactured from various metal alloys. Also, these include nickel, iron, chromium, molybdenum, and copper. These alloys are found in several grades and sizes ranging from 0.5 to 5.0 inches in diameter and 3.25 inches to 8.0 inches. Alloy steel is available in rods, bars, and sheets.

Strength of A182 F1 Alloy Steel Round Bars

Various alloy steel round bars are available in the market. Also, these are manufactured using the best quality raw materials. They are used in many industrial applications, are highly durable, and provide excellent strength. These are also known for high-temperature oxidation resistance. Also, these round bars are offered in different grades. The most common application of these bars is shafts. These bars are a good choice for manufacturing machinery. These are mainly manufactured by using a combination of rolling and forging. They have excellent tensile strength. Also, they are highly durable and have incredible dimensional precision. They are also offered in standard stock. These can be cut to any length. These are also commonly used in storage industries.

Cost-effectiveness

Choosing a supplier for cost-effective section steel can be a daunting task. But with local suppliers, you can get all types of sections at affordable prices. Alloy steel round bars are used in many industries, mainly manufacturing and engineering construction. Also, these bars are used in transport and residential buildings. They are made from different metal alloys and have other specifications. They are highly durable and can withstand high temperatures. Also, they are corrosion-resistant and can be used in various applications. Alloy steel A182 F1 Material round bar has good flexibility and tensile strength. Also, it has better resistance to oxidation and pitching. It is used in chemical equipment and pharmaceutical machinery. During the manufacturing process, these bars undergo different tests to ensure quality. They include positive material identification testing, mechanical testing, IGC testing, and flattening testing. These tests help guarantee the best bar quality to the industry.

Quality of A182 F1 Alloy Steel Round Bars

Obtaining high-quality alloy steel round bars for industrial applications is possible when you consider the many advantages that come from the use of alloy steel. They are suitable for many applications and withstand heavy loads and high temperatures. Alloy steel round bars are manufactured from superior-quality raw materials. Their high chromium content enhances their ability to resist scaling at high temperatures. They also have excellent wet corrosion resistance. Often, they are used in pumps, heat exchangers, and other applications. These round bars are available in different sizes, grades, and specifications. They are also available in various surface finishes. They are commonly used in aerospace components, jet engines, storage facilities, and non-residential construction.

Comments