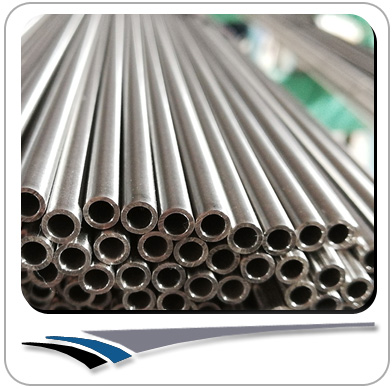

Frequently, piping systems for transporting fluids or gases use stainless steel pipes. Steel pipe produced by Stainless Steel Pipe suppliers in India is made from an alloy of steel that includes nickel and chromium, which gives stainless steel its corrosion-resistant qualities. Because stainless steel pipe doesn't oxidize, it's a low-maintenance option that works well in chemical and high-temperature applications. Stainless steel pipe is preferred for applications involving food, beverages, and pharmaceuticals due to how simple it is to clean and disinfect.

The most prevalent methods for producing stainless steel pipes are welding and extrusion. Steel produced by SS Welded Pipe manufacturers in India is formed into a pipe shape during the welding process, and the seams are then joined by welding to maintain the shape. Extraction produces a seamless product by heating a steel rod and then piercing it through the center to form a pipe.

Carbon steel is used to prevent corrosion in oil and gas wells.

Bimetallic combination tubing, which has an internal liner consisting of stainless steel, titanium alloy steel, copper or aluminum, etc., uses carbon steel pipe produced by Carbon Steel Pipe suppliers in India as its base pipe. High mechanical performance, weldability, high operational convenience, and high safety are characteristics of this type of tubing. It has high applicability because it combines a surface coating technology with low cost and broad useable range with a corrosion-resistant alloying technique with complete structure and high tightness (no blowhole) of material. You can look for the best Alloy Steel Tubes manufacturers in India.

In addition to having a stronger corrosion resistance than carbon steel pipe, bimetallic combination tubing is more affordable than diphase stainless steel and nickel-based alloy steel. It is frequently used in the oil and gas sector and exhibits very high-cost performance, particularly in environments with high chloride corrosion rates.

What is an alloy steel pipe?

Applications where moderate corrosion resistance, good durability, and an affordable price are required to use alloy steel pipes produced by Alloy Steel Pipe suppliers in India. Simply put, alloy pipes are chosen where carbon steel pipes could malfunction. High alloy and low alloy steels are the two categories of alloy steels. Low alloy steel pipes include an alloying level typically less than 5%. High alloy steel would have an alloying content that ranged from 5% to roughly 50%. Like most alloys, seamless alloy pipes have a working pressure capability approximately 20% higher than welded pipes.

Steels made of carbon and stainless Seamless and Welded Pipe

The two most widely utilized types of standard pipe in use today are stainless steel pipe and carbon steel pipe. They are a component of tubular goods produced by various norms and requirements. Pipes are sold in diameters ranging from 1/8" to 72" by "nominal pipe size." Welded pipes and seamless pipes produced by API 5L Grade B Pipe suppliers are the two most typical forms of pipes. Both are offered in stainless steel and carbon steel. A53 is the most popular specification for welded carbon steel pipe. The procedure used to create seamless pipes does not include welding. A106B is the most popular specification for seamless carbon steel pipe. A312 specifications are followed for manufacturing stainless steel pipes.

Comments