Quality control is a critical aspect of manufacturing and packaging industries, ensuring that products meet established standards for safety, durability, and performance. Several testing instruments, such as top load testers, salt spray chambers, torque testers, and scuff testers, play a pivotal role in evaluating various parameters to maintain the integrity of products.

Top Load Tester

A top load tester is essential for assessing the compressive strength of packaging materials like bottles, containers, and jars. It determines the maximum load that a container can withstand without deforming or failing, ensuring that products can endure stacking during storage and transportation. The tester applies a vertical load to the sample until deformation occurs, providing insights into the material's structural integrity. This test helps manufacturers optimize packaging design and material usage, enhancing product safety and reducing costs.

Salt Spray Chamber

Salt spray chambers are used to evaluate the corrosion resistance of materials, coatings, and surface treatments. In industries such as automotive, aerospace, and marine, where products are exposed to harsh environmental conditions, ensuring corrosion resistance is crucial. The salt spray chamber simulates a corrosive environment by spraying a salt solution on the test samples. This accelerated testing method helps predict the long-term effects of corrosion, allowing manufacturers to improve material formulations and protective coatings. By identifying potential weaknesses early, companies can enhance the durability and lifespan of their products.

Torque Tester

The torque tester measures the force required to open or close caps and closures, which is essential for products packaged in bottles or containers. Proper torque levels are crucial for maintaining product freshness, preventing leaks, and ensuring consumer safety. Too much torque can make a cap difficult to open, while too little can result in leaks. The torque tester provides precise readings, helping manufacturers set optimal torque specifications that balance user convenience and product integrity. This testing also helps in verifying the performance of capping machines, ensuring consistent application in production lines.

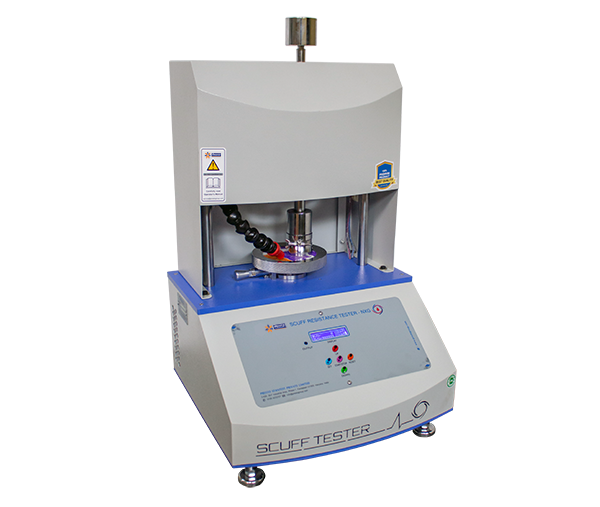

Scuff Tester

A scuff tester evaluates the abrasion resistance of printed or coated surfaces on packaging materials, such as labels and cartons. It simulates the wear and tear that packaging may encounter during handling, shipping, and storage. The scuff tester measures the resistance of surfaces to scuffing, rubbing, and abrasion, ensuring that labels remain legible and visually appealing throughout the product's lifecycle. This test is crucial for maintaining brand integrity and ensuring that packaging maintains its aesthetic quality in the marketplace.

Each of these testing instruments serves a unique purpose in the quality control process, but together they provide a comprehensive evaluation of a product's performance under various conditions. The top load tester ensures structural integrity, the salt spray chamber tests for corrosion resistance, the torque tester verifies proper sealing, and the scuff tester checks the durability of printed surfaces. By utilizing these tools, manufacturers can ensure that their products not only meet but exceed industry standards, leading to higher customer satisfaction and reduced product failures.

Comments