What is Inconel 800 Round Bar?

Inconel's grade number is 800. The grade 800 has a variant known as 800H. In some ways, the 800 and 800H are the same. The distinction between other grades of Inconel and 800 is that the latter is made up of Nickel and Cobalt. The grade's chemical composition is Nickel and Cobalt at a maximum of 35.0 percent, Cobalt separately at 2.00 percent, Chromium at a maximum of 23.0 percent, Copper at 0.75 percent, Manganese at 1.50 percent, and Aluminium at 0.60 percent. Inconel 800 has mechanical properties such as tensile strength of 75 Ksi and 520 MPa, yield strength of 30 Ksi and 205 MPa, and elongation of 30%.

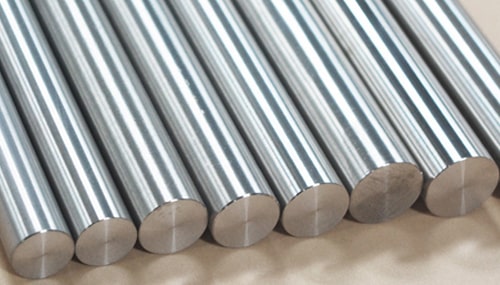

Inconel 800 round bars is a substantial alloy that is used in a variety of applications. Round Bars are similar to regular bars but are round in shape. The bars are made in a variety of shapes such as squares, rectangles, rounds, hexagons, and so on. Inconel 800 and 800H are identical in every way, and either can be used in any application; however, both grades perform equally well when used. The size may range from 6mm to 120mm, and the length may be uniform or customized. Finished round bars are available in Bright, Polished, and Black. The bars can be used as they are or they can be cut and made into a completely new product. Inconel 800 round bars are made of an iron-nickel-chromium alloy that is highly resistant to corrosion and oxidation. This round bar can withstand high temperatures. Inconel 800 can be forged into sheets, plates, tubes, pipes, bars, rods, flanges, fasteners, pipe fittings, and so on. All of these products are in high demand in a variety of industries.

Applications of Inconel 800 Round Bars?

Both alloy grades are widely used in a variety of industries. Inconel 800 and 800H Round Bars are primarily used in industries such as de-aerating heaters, marine engineering, chemical, and hydrocarbon processing equipment, gasoline and fresh water tanks, boiler feedwater heaters and other heat exchangers, valves, pumps, shafts, fittings, and fasteners, industrial heat exchangers, crude petroleum stills, chlorinated solvents, and crude oil distillation towers. All of the industries mentioned above rely heavily on Inconel 800 and 800H because it is an alloy that can withstand the harsh conditions and temperatures of the. This grade of the product is manufactured in large numbers and quantities.

Comments