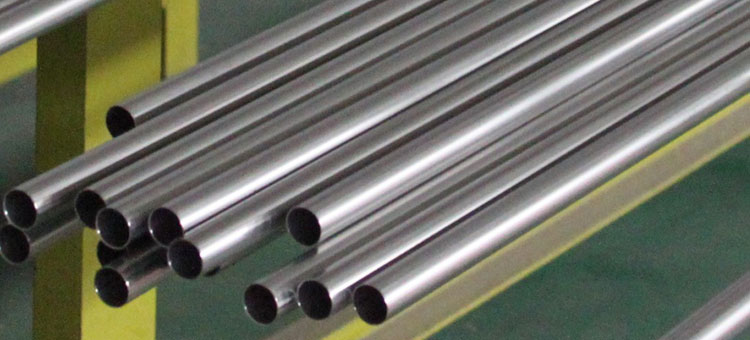

ASTM B622 UNS N10276 Seamless Pipes

One industry where equipment, like Hastelloy C276 Pipe, is subjected to a variety of environmental variables and chemical compositions is the production of pharmaceuticals. In light of this, the SB 622 UNS N10276 pipe, which is employed in the manufacturing of pharmaceuticals, is well suited for exposure to both low and high temperatures. Hastelloy is one of the least toxic alloys that are widely accessible worldwide despite this.

In actuality, when in contact with numerous pharmaceutical formulations, the ASME SB619 pipe does not result in harmful responses. This is likely the reason Hastelloy C276 is used in different components of the pharmaceutical production industries, including reactor vessels, flanges, and fittings, or the DIN 2.4819 pipe that is utilized in piping systems as well as in pumps and valves.

Advantages Of N10276 Seamless Pipes

A variety of settings benefit from the remarkable corrosion resistance of the C276 nickel-chromium-molybdenum-tungsten alloy. The high nickel and molybdenum contents are mostly to blame for this.

Additionally resistant to stress-corrosion cracking and pitting is this alloy. Waste fluid treatment systems are just one of the many applications where it is a great choice.

There are many different sizes and lengths of Hastelloy C276 seamless pipes available. They can be altered to suit certain requirements.

Both the chemical processing industry and the oil and gas business frequently employ these pipes. They are also appropriate for usage in marine settings.

These alloys are suitable for a variety of applications because they can be easily cut at moderate cutting rates. They work well with a variety of welding methods as well. Due to their low carbon content, welding does not result in the precipitation of grain boundary carbide. This maintains the heat-related corrosion resistance of the welded joints.

SB 622 UNS N10276 Pipes

The term "ASTM B622" is most likely referring to the American Society for Testing and Materials (ASTM) specification for seamless nickel and nickel-cobalt alloy pipe. The super alloy UNS N10276, often known as Hastelloy C-276, is described in this ASTM specification.

Applications requiring strong corrosion resistance, like chemical processing, pollution control, and waste treatment, employ SB 622 UNS N10276 pipe. By lowering acids, salts, and chloride-containing solutions, the special proportions of molybdenum, chromium, tungsten, and nickel in UNS N10276 offer it outstanding corrosion resistance.

It's crucial to remember that even though UNS N10276 is specified by ASTM B622, the specification only establishes the very minimum standards for the material's chemical makeup and mechanical characteristics. Depending on the needs of a given application, additional certifications, testing, or specifications may be required.

Comments