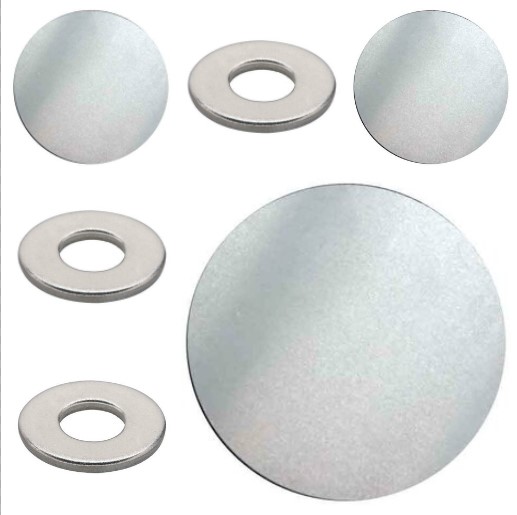

What are rings and circles Inconel 718

Inconel 718 Circle & Ring is the most widely used industrial raw material in various shapes and sizes. These rings form a strong bond with the oxide scale, which resists leakage, even in conditions of strong thermal cycling. These rings are used from cryogenic temperatures up to a long service life of 1200 degrees F. Inconel 718 rings provide optimal transverse ductility in heavy sections, impact toughness, and low tensile strength. Thanks to their unique range of functions, Alloy 718 rings are popular in many different critical industries and applications.

Features of circle and rings Inconel 718:

It offers some unique features such as efficiency, dimensional accuracy, durability, reliability, testing and short market price. It is non-magnetic, has excellent mechanical properties and is a desirable combination of high strength and good weldability over a wide temperature range.

Advantages of Inconel 718 circle and ring:

The nickel ring alloy 718 withstands a wide range of temperatures while maintaining creep resistance, corrosion resistance, high tensile strength, and yield strength to prevent stress breakage under normal operating conditions. Welding these rings in an aging state will cause a soft heat affecting configuration where there is enough time to allow air cooling after welding or annealing. Therefore, these ring materials suitable for operation in extreme conditions are exposed to pressure and heat that can be welded in obsolete or annealed conditions.

Uses of Inconel 718 circle and rings

Gas turbine components, cryogenic tank, jet engine, the pump body and parts, rocket engines and inverters, nuclear fuel cell spacer, and hot extrusion tools.

Comments