Inconel 600 is a chromium-nickel alloy designed for usage at temperatures below 2000 degrees Fahrenheit and with low cryogenic. The alloy is resistant to the dropping environment as well as chloride to stress corrosion cracking due to the material's resistance to chromium-nickel and weak oxidation circumstances. Inconel 600 is a non-magnetic supporting alloy with outstanding mechanical capabilities at cryogenic and high temperatures, because of its high nickel concentration. At high temperatures in the environment, nickel's material renders it vulnerable to sulfur-bearing assaults.

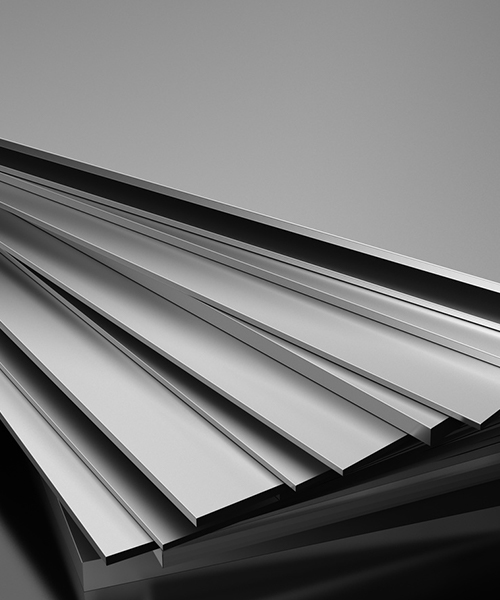

What is Inconel 600 Sheet?

Many well-known makers and suppliers offer Inconel sheets, such as the Inconel 600 Sheets, making them stand out from the crowd. The vast selection of Inconel 600 sheets is devoted to delivering a stable market. They sell it to overseas customers at a fair price that meets national and international quality standards. Inconel sheets that have been well-oxidized are oxidation and corrosion-resistant materials that can be used in harsh conditions with high pressure and kinetic energy.

Inconel 600 Sheets are also available in a variety of standards, including Inconel Sheets, Inconel Polished Sheets, Inconel Alloy Sheets, ASTM B168 Inconel Alloy Sheets, ASME SB 168 Inconel Cold Rolled Sheet Stockist, Inconel Plain Sheets, Inconel Shim Sheet, Inconel Perforated Sheet Exporters, Inconel Plain Sheets, Inconel Shim Sheet, Inconel Perforated Sheet Pollution control, waste treatment facilities, food processing, pulp and paper, and petrochemicals are among the applications for which it is suitable.

Many successful tests have resulted in increased demand as a result of the demand of leaflet buyers. Other tests include bend test, effect test, and radiography test, as well as Positive Material Recognition Test, Intergranular Ruston Test, Fighting Resistance Test, Flattening Test, Flaring Test, Macro Test, Micro Test, Hydrostatic Test, Mechanical Test, Chemical Test, and others. It's also done to guarantee that the product is consistent and complete.

Features of Inconel 600 Sheets

Exposure to saltwater: Because of its exceptional resistance to sodium chloride, Inconel 600 plates, coils, and sheets can be used in maritime applications.

Heat treatment applications- Inconel 600 sheets, plates, and coils are resistant to high temperatures and pressures while maintaining tensile strength. As a result, it's perfect for a variety of heat-treatment applications.

It has merged low and high-temperature processes, resulting in rapid temperature change. It has great oxidation resistance at both low and high temperatures, making it suitable for use in processes.

Comments