Introduction

Finland, a nation at the forefront of technological adoption, is increasingly recognizing the transformative power of Artificial Intelligence (AI) and the Internet of Things (IoT) in revolutionizing its logistics sector. Within this landscape Finland ATLS Market stand to gain significantly from the integration of these cutting-edge technologies. This article explores the pivotal role that AI and IoT are playing and will continue to play in optimizing ATLS operations across Finland, focusing on the concepts of predictive loading and the achievement of real-time efficiency throughout the supply chain.

Understanding the Current State of ATLS in Finland:

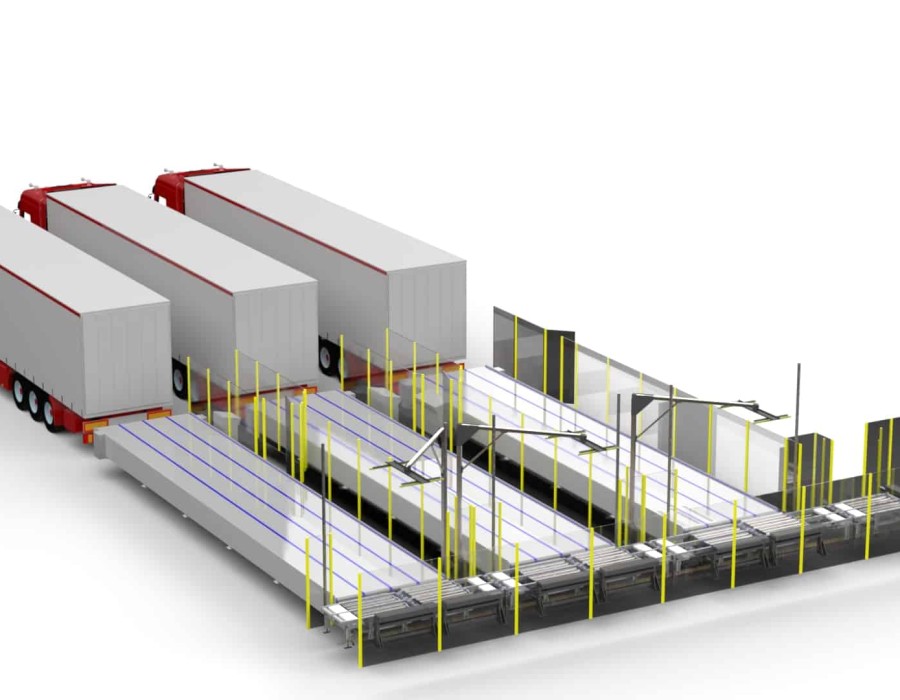

Finland's logistics landscape already benefits from the implementation of ATLS in various industries, streamlining the loading and unloading of standardized goods. These systems have proven effective in reducing manual labor, minimizing turnaround times, and enhancing overall efficiency. However, the next wave of optimization lies in leveraging the vast potential of AI and IoT to introduce a new level of intelligence and responsiveness to these automated processes.

The Synergistic Power of AI and IoT in Logistics:

AI and IoT are not independent entities but rather complementary technologies that, when combined, create a powerful ecosystem for intelligent logistics:

- IoT as the Data Foundation: IoT devices, such as sensors, RFID tags, GPS trackers, and smart cameras, act as the eyes and ears of the logistics operation, collecting a continuous stream of real-time data on various parameters. This data includes information on truck location, load weight, temperature, humidity, equipment status, and even the condition of the goods being transported.

- AI as the Intelligent Brain: AI algorithms, including machine learning (ML), natural language processing (NLP), and computer vision, analyze the massive datasets generated by IoT devices. This analysis enables the system to identify patterns, predict future outcomes, automate decision-making, and optimize processes in real time.

Predictive Loading: Anticipating Needs and Optimizing Before Execution:

One of the most significant advancements enabled by the integration of AI and IoT in Finland's ATLS market is predictive loading. This concept goes beyond simply automating the physical loading process and involves using data-driven insights to anticipate loading needs and optimize the process before it even begins. This can be achieved through:

- Demand Forecasting: AI algorithms can analyze historical sales data, seasonal trends, market forecasts, and even external factors like weather patterns to predict future demand for specific goods. This allows logistics operators to proactively plan loading schedules and allocate resources efficiently.

- Inventory Management Optimization: Real-time inventory data from IoT-enabled warehouses and distribution centers, combined with AI-powered analytics, can predict when and where specific goods will be needed. This enables proactive staging and optimized loading sequences to meet anticipated demand.

- Vehicle Routing and Load Planning: AI algorithms can analyze real-time traffic data, delivery schedules, and the characteristics of the goods to be transported to optimize vehicle routes and plan the most efficient loading configurations. This includes determining the optimal sequence of loading items to ensure efficient unloading at multiple destinations and balanced weight distribution.

- Predictive Maintenance for ATLS Equipment: IoT sensors embedded in ATLS equipment can monitor their performance and identify potential maintenance issues before they lead to breakdowns. AI algorithms can analyze this data to predict when maintenance will be required, allowing for proactive scheduling and minimizing downtime, ensuring continuous loading operations.

- Optimizing Loading for Specific Destinations: AI can analyze delivery schedules and the order of stops to optimize how goods are loaded onto the truck, ensuring that items needed first are easily accessible, minimizing unloading time at each destination.

Real-Time Efficiency: Dynamic Optimization and Adaptive Operations:

The combination of AI and IoT also enables real-time efficiency in Finland's ATLS operations, allowing for dynamic adjustments and adaptive responses to changing conditions:

- Real-Time Load Monitoring and Adjustment: IoT sensors can continuously monitor the weight distribution and stability of the load during transit. If imbalances are detected, the system can alert the driver or even trigger automated adjustments at the next loading/unloading point, ensuring safety and preventing damage.

- Dynamic Route Optimization: Real-time traffic data from IoT-enabled navigation systems, combined with AI algorithms, allows for dynamic route adjustments to avoid congestion and delays, ensuring timely deliveries and maximizing the utilization of ATLS at the destination.

- Condition Monitoring of Goods: For temperature-sensitive or fragile goods, IoT sensors can monitor their condition in real time. If deviations from the required parameters are detected, alerts can be sent, and proactive measures can be taken to prevent spoilage or damage, optimizing the entire cold chain or handling process involving ATLS.

- Automated Exception Handling: AI algorithms can be trained to identify and respond to exceptions or disruptions in the loading or transportation process, such as unexpected delays or changes in delivery schedules. This automated exception handling minimizes manual intervention and ensures a more resilient and efficient operation.

- Data-Driven Performance Analysis and Continuous Improvement: The continuous stream of data generated by IoT devices and analyzed by AI provides valuable insights into the performance of ATLS operations. This data can be used to identify bottlenecks, optimize processes, and drive continuous improvement over time.

Benefits of AI and IoT Integration in Finland's ATLS Market:

The integration of AI and IoT into Finland's ATLS operations offers a wide range of compelling benefits:

- Enhanced Operational Efficiency: Predictive loading and real-time optimization minimize wasted time, reduce manual effort, and accelerate the entire loading and unloading process.

- Reduced Transportation Costs: Optimized loading, efficient routing, and proactive maintenance contribute to lower fuel consumption, reduced vehicle wear and tear, and minimized downtime.

- Improved Safety and Security: Real-time load monitoring and predictive maintenance enhance safety during transit and loading/unloading operations. AI-powered security systems can also help prevent theft and tampering.

- Increased Supply Chain Visibility: Real-time data on the location and condition of goods provides end-to-end visibility across the supply chain, enabling better decision-making and improved customer service.

- Minimized Errors and Damage: Precise automated loading guided by AI and real-time monitoring reduces the risk of loading errors and damage to goods.

- Sustainable Logistics Practices: Optimized routes, reduced fuel consumption, and efficient resource utilization contribute to more environmentally friendly logistics operations.

- Improved Customer Satisfaction: Timely deliveries, accurate order fulfillment, and real-time tracking enhance customer satisfaction.

- Data-Driven Decision Making: The wealth of data generated and analyzed provides valuable insights for strategic decision-making and continuous improvement.

Challenges and Considerations for Implementation:

While the potential of AI and IoT in Finland's ATLS market is significant, successful implementation requires careful consideration of several challenges:

- Initial Investment Costs: Implementing IoT sensors, AI software, and the necessary infrastructure can involve significant upfront investment.

- Data Security and Privacy: Handling large volumes of sensitive logistics data requires robust security measures and adherence to privacy regulations.

- Integration Complexity: Integrating AI and IoT systems with existing ATLS infrastructure and other enterprise systems can be complex and require specialized expertise.

- Data Management and Analysis Capabilities: Effectively leveraging the data generated requires robust data management platforms and skilled data scientists and analysts.

- Interoperability and Standardization: Ensuring interoperability between different IoT devices and AI platforms is crucial for seamless data exchange and system integration.

- Talent Acquisition and Training: A skilled workforce is needed to implement, manage, and maintain these advanced technologies. Investing in training and attracting talent is essential.

- Resistance to Change: Overcoming potential resistance to adopting new technologies within the workforce requires effective communication and change management strategies.

The Future Trajectory: AI and IoT as Core Components of Finland's Smart Logistics:

The integration of AI and IoT is not just a trend but a fundamental shift towards smart logistics in Finland. As these technologies continue to mature and become more accessible, their role in optimizing ATLS operations will only become more pronounced. We can expect to see:

- More Autonomous Loading Systems: AI-powered robots with advanced vision and manipulation capabilities will increasingly automate the loading and unloading of even complex and non-standardized goods.

- Hyper-Personalized Logistics: AI will enable highly customized loading and delivery solutions tailored to the specific needs of individual customers.

- Digital Twins for ATLS Optimization: Virtual representations of ATLS operations, powered by real-time IoT data and AI simulations, will allow for proactive optimization and scenario planning.

- Edge Computing for Faster Decision Making: Processing data closer to the source (on the edge) will enable faster real-time decision-making and reduce latency in ATLS operations.

- Block chain for Enhanced Transparency and Security: Block chain technology can be integrated to provide a secure and transparent record of loading and transportation events.

Conclusion

Finland's commitment to technological innovation positions it perfectly to leverage the transformative power of AI and IoT in optimizing its Automated Truck Loading Systems. By embracing predictive loading and striving for real-time efficiency, Finnish logistics companies can unlock significant improvements in operational efficiency, cost-effectiveness, safety, and sustainability. While challenges related to implementation need to be addressed strategically, the long-term benefits of creating an intelligent and responsive logistics ecosystem are undeniable. The integration of AI and IoT is not just about automating tasks; it's about creating a smarter, more efficient, and ultimately more competitive future for Finland's logistics sector, with ATLS playing a central and increasingly intelligent role.

Comments