Why Wire Harness Manufacturing is Essential for Industrial Automation

Introduction

Wire harness manufacturing is a basic part of industrial automation, empowering proficient associations between different gadgets and systems to improve efficiency and unwavering quality.

Outline

Introduction

Job of Wire Harnesses in Industrial Automation

Key Advantages of Value Wire Harness Manufacturing

Challenges in Wire Harness Creation

Conclusion

FAQs

Background

Background

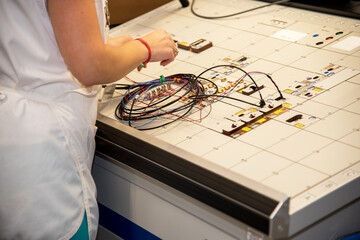

Wire harness manufacturing fills in as the foundation of industrial automation, giving the important electrical associations that help mechanized hardware and systems. With the rising intricacy of industrial conditions, the interest in dependable and effective wire harnesses has developed essentially, driving advancement and quality in manufacturing processes.

Job of Wire Harnesses in Industrial Automation

Wire harnesses work with correspondence between sensors, regulators, and actuators in computerized systems, guaranteeing consistent information movement and functional proficiency.

Key Advantages of Value Wire Harness Manufacturing

Further developed Proficiency: Top-notch wire harnesses decrease personal time by guaranteeing solid associations and limiting disappointments.

Improved Wellbeing: Appropriately produced harnesses assist with forestalling electrical dangers, adding to more secure workplaces.

Customization: Makers can fit wire harnesses to meet explicit automation needs, requiring different applications and conditions.

Challenges in Wire Harness Creation

Normal difficulties incorporate overseeing complex designs, guaranteeing consistency with industry principles, and keeping up with excellent creation in enormous volumes.

Conclusion

Wire harness manufacturing is essential for the outcome of industrial automation, driving proficiency, security, and customization in current manufacturing conditions.

FAQs

1. What is the essential capability of wire harnesses in industrial automation?

Wire harnesses interface different mechanized parts, empowering effective correspondence and control.

2. How does the nature of wire harnesses influence industrial automation?

Quality harnesses improve system dependability and decrease the risk of disappointments.

3. Could wire harnesses be modified for explicit industrial applications?

Indeed, they can be intended to meet the extraordinary necessities of various automation systems.

4. What difficulties do makers look into in wire harness creation for automation?

Challenges incorporate overseeing intricacy, guaranteeing consistency, and keeping up with top-notch in huge-scope creation.

5. Why is well-being significant in wire harness manufacturing for industrial automation?

Well-being is vital to forestall electrical dangers and guarantee a safe workplace for administrators.

Comments