Introduction

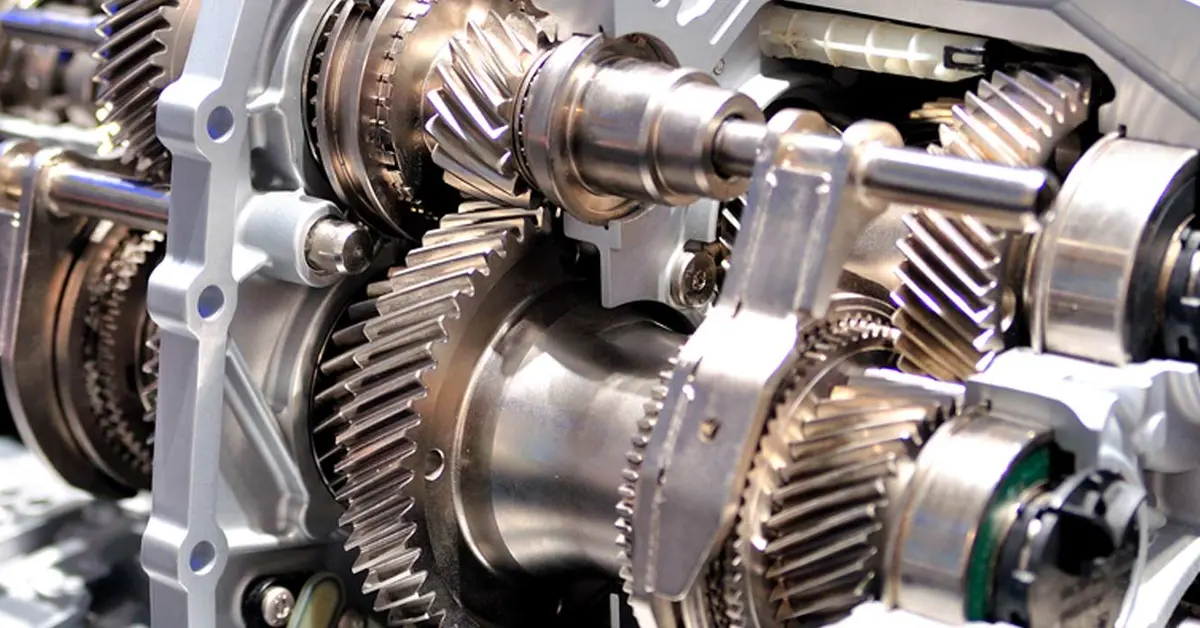

Milling machines make manufacturing easier, allowing operators to remove metal fragments by utilizing a rotating cutter. The cutter rotates at a high speed, facilitating effective cutting through metal. These cutters come up with a cutting edge that plays a vital role in cutting materials. used portal milling machine is also a good option for manufacturing precision cuts and parts that you can consider when you’ve a limited budget.

One cutter is required at a time in operating milling machines. It is one of the most important machines you can easily find in a workshop. These machines allow operators to perform operations with ease of access and high accuracy. It cuts material faster and at a higher rate than other similar machines such as lathe. You can also consider used milling machine that manufacture quality material at an affordable and cost-effective solution.

Universal Milling Machine

A universal milling machine can perform various tasks and table rotates at any angle for up to 45 degrees on both sides. The horizontal milling machine can rotate in three directions and also has a rich feature of fourth movement. Additionally, this machine is capable of helical milling. The machine's capacity can also be increased by adding more attachments. You can add more attachments to this machine to speed up the process or capacity. Some special attachments are as follows:-

- Slotting attachment

- Rotary attachment

- Vertical milling attachment

- Index head or dividing head

Vertical Milling Machines

The spindle of a vertical milling machine is positioned vertically and perpendicular to the work table. The cutting tool's movement can be easily and precisely controlled thanks to this design. These types of milling machines are excellent options for performing tasks like face milling and end milling, which are known for stability for vertically oriented tasks.

Turn-mill machine

Turn-mill machine, a hybrid CNC machine, combines a blend of performing milling and turning capabilities that meet accuracy and streamlined machining processes. This machine is familiar because it is a quick, strong, and adaptable device that can perform intricate tasks more accurately and quickly than other conventional machines.

Knee Type Milling Machine

Knee-type milling machines boast a worktable that can adjust vertically and are supported by an adjustable knee, allowing operators to move up or down. Because of its adjustable worktable design, this design can be used for a wide range of machining applications.

Bed-Type Milling Machine

Bed-type milling machines are placed directly onto the massive bed of the machine and cannot be raised or moved transversely. The machine is known for its stability and versatility, making it a popular choice for manufacturing complex parts. Industries that require accuracy and consistency, like aerospace and automotive manufacturing, tend to favor bed mills.

Discover accuracy and consistency with a used AXA VHC-3 for sale now listed on the website. This vertical milling machine offers unparalleled accuracy and renders top-notch performance.

Wrapping It Up

Milling machines are the cornerstone of the manufacturing of automotive parts, allowing operators to manufacture intricate components and products across various industries. Whether it is Bed-Type, knee-type, or vertical - each milling machine has its own characteristics. Choose one milling machine that suits your workshop requirements.

Comments