If you are working on a project that includes compression springs, understanding how to degree them successfully is critical. Whether you need small compression springs or big compression springs, getting the measurements proper ensures that your springs function effectively. Here is a short guide on how to measure helical compression springs for your project.

Step 1: Identify the Type of Spring

Identify the type of spring since it forms the basis of your work. Helical compression spring represent most compression springs because they exhibit a spiral design. The loading process causes compression springs to reduce their size before they automatically recover their initial dimensions after the applied force disappears. Before starting any work, you need to recognise the specific spring type regardless of whether you use stainless steel compression springs or different materials.

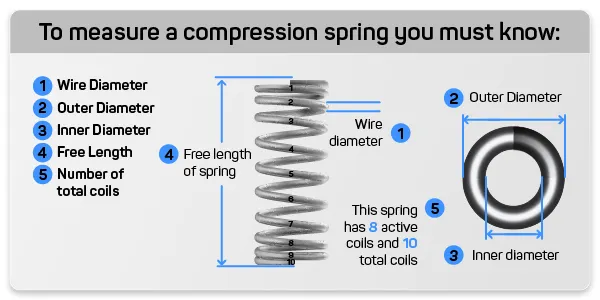

Step 2: Measure the Outer Diameter

The measurement of the spring’s outer diameter stands as one of the primary factors. Using a calliper will help you determine the largest distance within the spring. This measurement determines the amount of space that the spring requires for your project. The correct measurement determines how well the spring fits its intended area.

Step 3: Measure the Wire Diameter

Spring wire thickness determines its diameter through size measurement. The measurement’s precision of wire diameter has direct consequences for the spring force production together with its operational performance. A micrometre should be utilized to measure wire dimensions in either millimetres or inches while working with your system. As a result, you will obtain data that establishes the spring’s maximum load capacity.

Step 4: Measure the Spring’s Length

Take note of the natural length of the spring before any compression occurs. The spring assumes this measurement when it operates without compression forces. A ruler or calliper serves as the appropriate tool to conduct the measurement. The correct operation of a spring depends on knowing its free length for installation purposes.

Step 5: Count the Number of Coils

The spring design requires precise counting of its coil arrangement. A helical spring forms through wire coils, which influence the spring’s behaviour according to coil count. The measurement of coil count requires inspecting the full turns of the spring itself. The spring becomes softer when the number of coils increases, yet it becomes stiffer when the number of coils decreases.

Step 6: Calculate the Spring Constant

The spring constant establishes the amount of force necessary to produce a specific distance of compression in the spring. The calculation method requires basic arithmetic that links to the wire diameter together with the outer diameter measurement and coil count data. Many spring producers maintain calculators which will guide anyone who needs help with these calculations.

Step 7: Consider the Material

You need to think about the material comprising the spring at the end of this evaluation process. Periodic usage of stainless steel compression springs makes them a preferred option because their combination of strength and high resistance to corrosion makes them suitable for various applications. Your application demands unique specifications for the material you will require. Consult your manufacturer’s documentation to locate guidance on materials that will best satisfy your needs.

Step 8: Order Compression Springs by Size

You can choose the suitable spring for your project after obtaining all required measurements. Your requirements fall within our product range since we supply large compression springs in various sizes that suit your needs. You should order compression springs according to their size dimensions to achieve perfect project fitment.

Conclusion

Measuring helical spring compression is necessary to ensure that your spring performs as expected. By following these steps, you will be able to measure your spring accurately and order the correct one for your project. If you are ever unsure, do not hesitate to consult a professional or use a reliable spring supplier, like Acxess Spring, for high-quality springs.

Comments