Extrusion Applications/Extrusion Applications in Chemical Industries/Top Extrusion Uses in Chemical Industries/Applications of Extrusion in Industries/Uses of Extrusion in Chemical Industries/

Table of Contents

- Extrusion Applications in Chemical Industries

- Introduction

- What is Extrusion?

- Types of Extrusion Processes

- Extrusion Applications in The Chemical Industry

- 1. Plastic Manufacturing

- 2. Rubber and Elastomer Production

- 3. Chemical Coatings and Film Extrusion

- 4. Composite Materials Manufacturing

- 5. Pharmaceutical and Food Processing

- How Kriimpas India Pvt. Ltd. Contributes to the Extrusion Process: Extrusion Applications in Chemical Industries

- 1. Extruder Machines and Components

- 2. Automation and Control Systems

- 3. Customized Solutions

- 4. Maintenance and After-Sales Support

- Conclusion: Extrusion Applications in Chemical Industries

Introduction

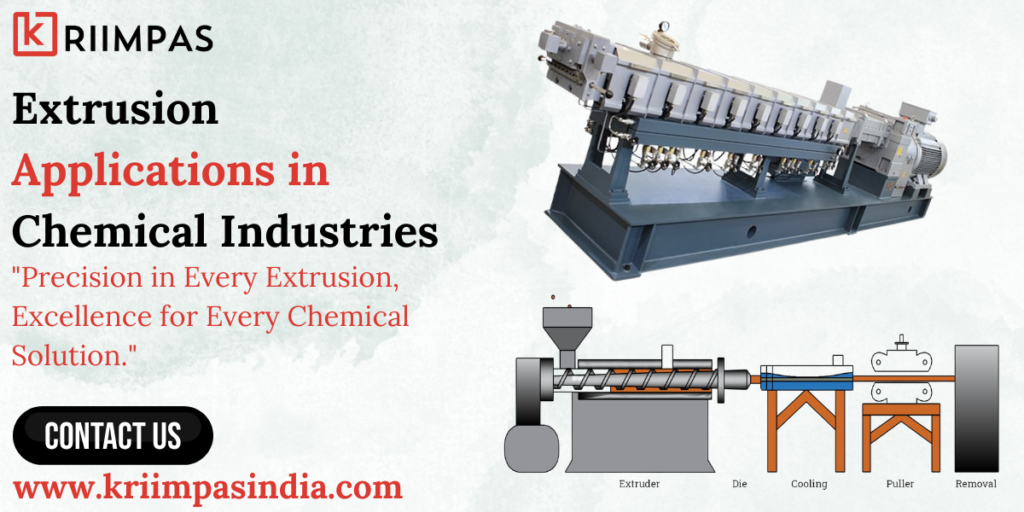

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers. We are the best provider of Extrusion Applications in Chemical Industries.

One important sector that propels the world economy is the chemical industry. Chemical manufacturers are constantly searching for cutting-edge technologies to improve their production processes because of the industry’s wide scope and ongoing need for innovation. Extrusion is one such technological innovation that has found extensive use in the chemical industry.

This article will explore the significance of extrusion in the chemical industry, its various uses, and the critical role that Kriimpas India Pvt. Ltd., a top provider of auxiliary machinery and services, plays in this field.

What is Extrusion?

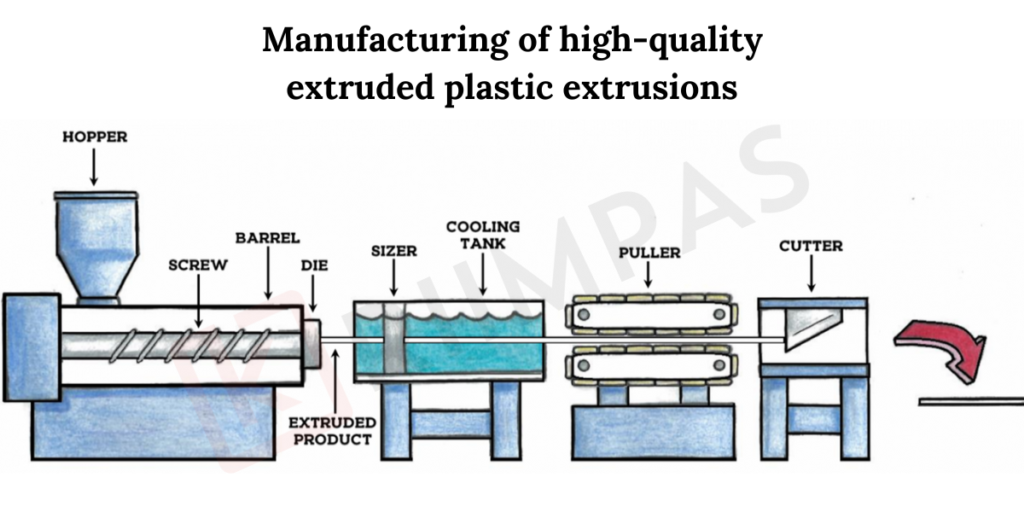

Extrusion is a manufacturing process that produces objects with a fixed cross-sectional profile by forcing raw materials through a die. Metals, polymers, and chemicals can all be shaped using this process into continuous shapes like sheets, pipes, or films.

Extrusion is frequently used in the chemical industry to produce goods like composite materials, pipes, plastic films, and chemical formulations. It makes use of extruders, which are devices made to apply pressure and heat to transform raw materials into finished goods.

Types of Extrusion Processes

The chemical industry makes use of a variety of extrusion process types, including:

- Hot Extrusion: The material is heated in the hot extrusion process before being pushed through the die. It is frequently applied to materials like rubber, polymers, and plastics.

- Cold Extrusion: This method works best with materials that are heat-sensitive because it takes place at room temperature. The primary applications of cold extrusion are in the production of chemical seals, gaskets, and specific chemical compounds.

- Blown Film Extrusion: This technique is used to create thin polymer films, which are frequently found in packaging materials. For a variety of uses, the extruded film can be cut into different sizes after being blown into a thin, consistent layer.

- Injection Moulding Extrusion: This method is widely used to produce complex and intricate shapes, making it perfect for use in precision-sensitive chemical products such as packaging and automobiles.

Extrusion Applications in The Chemical Industry

1. Plastic Manufacturing

The production of plastic is one of the most well-known uses of extrusion in the chemical industry. Numerous plastic products, such as pipes, sheets, films, and profiles, are made by extrusion. Numerous industries, including electronics, automotive, packaging, and construction, use these plastic materials. Manufacturers can design unique solutions that satisfy the needs of various industries by extruding plastics into precise sizes and shapes.

For example, extrusion processes are frequently used in the production of PVC pipes, polyethylene films, and polypropylene sheets. These materials demonstrate the versatility and necessity of extrusion in the chemical industry, as they are crucial in sectors like food packaging, construction, and agriculture.

2. Rubber and Elastomer Production

In the chemical industry, extrusion is also frequently utilised in the manufacturing of rubber and elastomers. Extrusion can be used to process rubber compounds, which are frequently used in tires, gaskets, and seals, to produce the appropriate shapes and sizes. Rubber extrusion is the perfect method for high-performance applications because it guarantees consistent product quality and accurate dimensions.

Furthermore, extrusion technology is frequently used to create the elastomeric materials used in the construction and automotive industries. Extrusion is a cost-effective and environmentally friendly solution because of its continuous nature, which guarantees effective production with little waste.

3. Chemical Coatings and Film Extrusion

Chemical coatings are frequently applied using extrusion. Extrusion aids in applying consistent coatings to materials like plastic films or metal wires in the production of coated wires and films. By increasing strength, preventing corrosion, and adding other useful qualities, chemical coatings improve the qualities of materials.

Coated cables, for instance, are extensively utilised in the electronics and telecommunications sectors, where environmental resistance is essential. Consistent coating thickness and excellent outcomes are guaranteed by the extrusion process.

4. Composite Materials Manufacturing

Extrusion is essential to the chemical industry’s production of composite materials, which are made by mixing various materials to improve strength, durability, and other desired properties. Extrusion techniques are frequently used in the production of plastic composites, carbon-fiber composites, and glass-reinforced composites. In sectors like construction, automotive, and aerospace, these materials are essential.

Because extruded composite materials are strong, lightweight, and adaptable, they can be used in a wide range of demanding applications. Manufacturers can create high-performance products by controlling the material’s properties during extrusion.

5. Pharmaceutical and Food Processing

Pharmaceutical pellets and food snacks are two examples of the uses for extrusion in the food processing and pharmaceutical industries. Products like food pellets, tablets, and capsules can be made with exact sizes and shapes thanks to the extrusion process. These substances can be utilised as ingredients in foodstuffs that are ready to eat or for controlled-release applications.

Extruded snacks are a popular product in the food industry. A dough-like substance is forced through an extruder, where pressure and heat cook it to create the finished product. Extrusion is a essential procedure in guaranteeing the creation of high-quality products because of its adaptability in these applications.

How Kriimpas India Pvt. Ltd. Contributes to the Extrusion Process: Extrusion Applications in Chemical Industries

A well-known brand in the chemical industry for auxiliary machinery and services, Kriimpas India Pvt. Ltd. provides a variety of goods and services that greatly improve extrusion applications. We are the best provider of Extrusion Uses in Chemical Industries. The business offers specialised machinery and equipment made to satisfy the unique requirements of chemical producers.

1. Extruder Machines and Components

High-performance extruder machines designed to produce reliable and effective results are produced by Kriimpas India. These devices are made to be used in a variety of chemical extrusion applications, guaranteeing that producers can produce the required results with a high degree of accuracy and little waste.

In order to maximise the extrusion process for chemical materials, the company provides a variety of extruder components, including screw elements, barrels, dies, and gears. Because these parts are essential to the durability and functionality of extrusion machines, Kriimpas India is a reliable partner in the chemical industry.

2. Automation and Control Systems

Controlling the process parameters and ensuring consistent quality are essential in the extrusion industry. Advanced automation and control systems from Kriimpas India Pvt. Ltd. enable producers to keep an eye on and modify extrusion parameters like temperature, pressure, and speed. These systems aid in making sure that production goes smoothly and that the final product satisfies the necessary requirements.

Kriimpas India helps its customers increase operational effectiveness, lower human error, and improve product quality by providing automation solutions. The company’s systems offer chemical manufacturers a complete solution by seamlessly integrating with their current extrusion lines.

3. Customized Solutions

The requirements of various industries can differ significantly, and each chemical manufacturing process is distinct. Knowing this, Kriimpas India provides specialised extrusion solutions to satisfy each customer’s unique needs. The engineering team at Kriimpas India is committed to creating and offering customised solutions for chemical extrusion processes, whether they call for a specific die, special heating system, or control mechanism.

The business’s capacity to offer custom equipment and services enables producers to streamline their workflows and produce superior goods more quickly.

4. Maintenance and After-Sales Support

Apart from offering top-notch extrusion equipment, Kriimpas India also provides thorough maintenance and post-purchase assistance. When it comes to machine installation, troubleshooting, and routine maintenance, the company’s team of professionals is always available to help. This guarantees maximum productivity and little downtime for manufacturers.

Kriimpas India’s remaining after-sales service, which assists customers in preserving the optimal performance of their extrusion systems, demonstrates the company’s dedication to long-term client satisfaction.

Conclusion: Extrusion Applications in Chemical Industries

Extrusion technologies are used extensively in the chemical industry to create a variety of materials that are essential to modern life. Extrusion is crucial in determining the direction of the chemical industry, from composite materials and pharmaceuticals to plastics and rubber.

With cutting-edge equipment, automation systems, and knowledgeable services that promote the expansion of the chemical industry, Kriimpas India Pvt. Ltd. is honoured to be at the vanguard of this revolution. Kriimpas India is your reliable partner for any extrusion-related needs, with an emphasis on innovation, quality, and client satisfaction. We are the best Supplier of Extrusion Applications in Chemical Industries.

Get in touch with Kriimpas India Pvt. Ltd. right now for customised solutions that can support the success of your company if you’re looking to improve your chemical manufacturing processes with cutting-edge extrusion tools.

Comments