What is Industrial Automation?

Industrial automation refers to the use of control systems—such as computers, robotics, and information technologies—to manage different processes and machinery in industries without the need for human intervention. These systems enable continuous, real-time operations, significantly reducing the time, effort, and resources required for production tasks. In the USA, the automation industry is highly diverse, serving various sectors such as automotive, electronics, aerospace, food and beverage, and pharmaceuticals.

The Rise of Industrial Automation in the USA

The United States has long been a leader in industrial innovation. industrial automation service usa With the advent of automation technology, manufacturers can now address several operational challenges, including labor shortages, rising labor costs, and the need for high-precision production. Industrial automation companies in the USA provide cutting-edge solutions that help firms maximize efficiency and stay competitive in both domestic and global markets.

The rise of Industry 4.0—a term used to describe the fourth industrial revolution—has further accelerated the adoption of automation. It involves the use of smart technologies like AI, the Internet of Things (IoT), and cloud computing, which allow machines and systems to communicate with each other, collect data, and optimize manufacturing processes in real-time.

Key Benefits of Industrial Automation

Increased Efficiency: Automation systems can work 24/7 without fatigue, leading to faster production rates and increased output. This boosts the overall productivity of a business, enabling it to meet higher demands without compromising quality.

Cost Reduction: By automating manual tasks, businesses can cut labor costs and reduce the occurrence of errors that lead to waste or rework. Additionally, the reduction in downtime due to predictive maintenance allows companies to optimize resource usage.

Improved Quality: Automated systems offer high precision and consistency, significantly reducing the risk of defects in manufactured goods. This leads to higher product quality, which is essential for industries like pharmaceuticals and electronics.

Safety: Automation reduces the need for human involvement in hazardous environments, minimizing the risks of workplace injuries. Robotics, for instance, can handle tasks in extreme temperatures, toxic atmospheres, or dangerous machinery environments.

Real-Time Data and Analytics: Industrial automation systems are equipped with sensors and connected technologies that provide real-time data on operations. This allows businesses to monitor performance, track production trends, and make data-driven decisions to further optimize processes.

Leading Industrial Automation Services in the USA

Numerous industrial automation companies in the USA offer a wide array of services tailored to different industries. These services include:

System Integration: Bringing together various subsystems to work as a single cohesive unit.

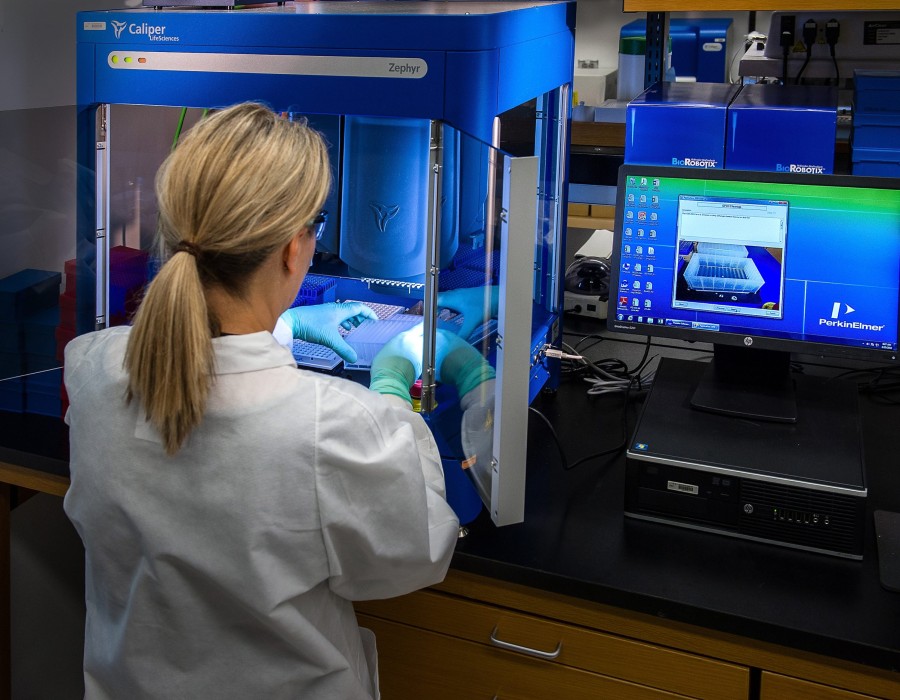

Robotic Automation: Deploying robots to handle repetitive or dangerous tasks.

PLC (Programmable Logic Controllers): Systems that automate machines or processes by using software.

SCADA (Supervisory Control and Data Acquisition): Technology for monitoring and controlling industrial processes remotely.

IoT Integration: Leveraging IoT devices to enable communication and data collection from machines.

The Future of Industrial Auto

mation

As technology continues to evolve, the future of industrial automation looks promising. advanced software engineering services Innovations in AI, machine learning, and IoT will drive even greater efficiency, flexibility, and sustainability in manufacturing processes. Smart factories equipped with fully automated systems will become the norm, enabling businesses to adapt to market changes quickly and efficiently.

Comments