Despite the revolutionizing applications of printed circuit boards (PCBs) in advanced electronics, they house devices ranging from smartphones to medical instruments within them. Understanding the dynamics of these PCBA circuit boards is very crucial if one intends to deal in these highly evolving electronics. Here, we dive into the assembly of printed circuit boards and explore the intricate processes that bring them to life.

Understanding PCBA and Its Significance

PCBA stands for Printed Circuit Board Assembly. It refers to the process for developing the electronic components place over PCB or printed circuit boards for realizing a functioning circuit. It is a key procedure in production and servicing of electronic devices, as it will amount to the operational ability of these devices. Therefore, it processes will be characterized by complex design and accurate implementation, making it the bedrock of advanced technology.

At PCB And Assembly, we basically build up and develop high-quality solutions according to international industry standards. Our expertise offers a wide range of services, making us a one-stop shop for all PCB and assembly needs across the globe.

The Role of Design in PCB Assembly

The story starts with the design of the PCB. Every trace, placement of a component, and layer has a function. A better-designed PCB will perform better without errors during assembly. Advanced software tools have a key role in turning ideas into PCB layouts to realize good manufacturing.

The earlier the design faults emerge, the more they tend to be expensive to rectify at a stage closer to production. Hence, this verification and testing will always have to be inherent in the entire process. Following solid design principles, then, is what makes people like PCBAndAssembly so reliable, delivering results that will survive even in real applications.

The Steps in PCB Assembly

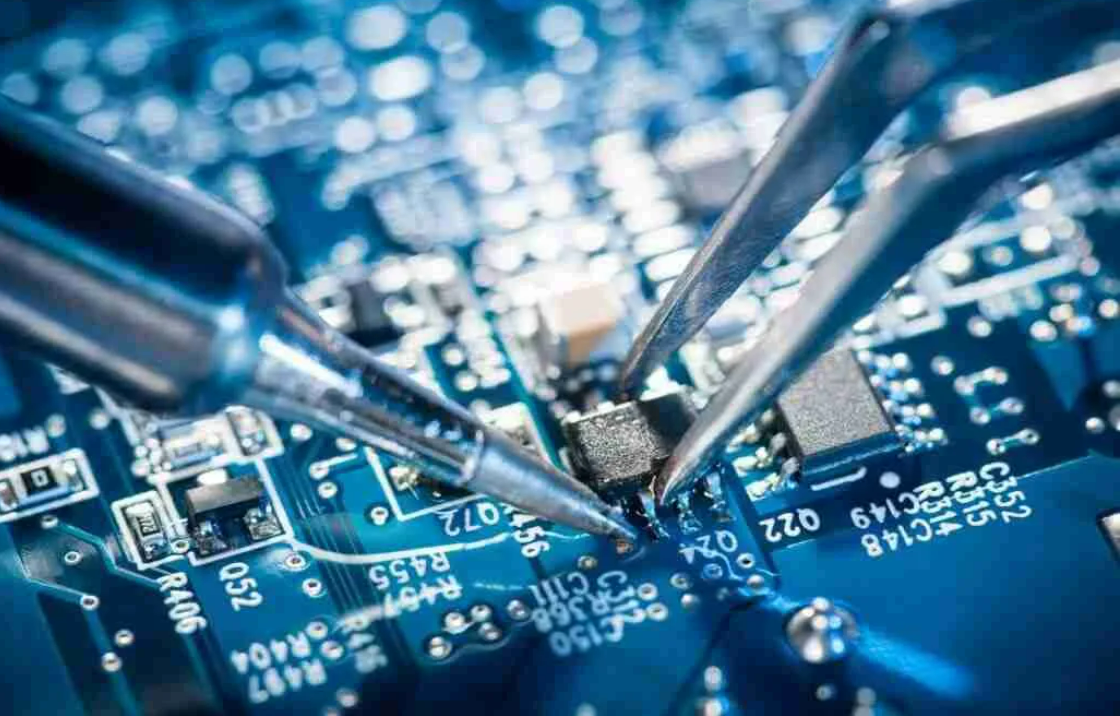

The assembly of printed circuit boards is a multi-stage activity where automatic precision meets skilled craftsmanship. First bare PCB is prepared for component placement. The primary methods used are Surface Mount Technology (SMT) or Through-Hole Technology (THT). SMT is the component-placement method that involves placing components directly onto the surface of the PCB; THT involves inserting each component lead into holes and soldering them in place.

Subsequently, the board is applied for solder paste, and components are placed using automated pick-and-place machines. After that, the board goes into the soldering process, which usually refers to a means of reflow ovens for SMT or wave soldering for THT. Then, the assembly will be inspected and tested.

Challenges in PCBA Circuit Board Production

PCBA can, however, be a challenge. The complexity starts in sourcing high-quality components and even extends to meeting tight deadlines. The rapidly changing technology landscape means that designs are becoming more complex and require modern equipment and very trained personnel.

Final Thoughts

The manufacturing process is only part of the picture. PCBA is an art and science that drives technology progress. Understanding what PCBA is and the elaborate steps involved in producing it will give keen insight into how these devices come alive before being plugged in and used by our daily lives.

Discover more about how we can support your business by visiting www.pcbandassembly.com . Let’s innovate together.

Comments