Rubber gaskets are critical components in various industries, serving as effective seals that prevent leaks, protect against contamination, and enhance the durability of mechanical systems. These versatile sealing solutions are designed to fill the gaps between two mating surfaces, ensuring a tight seal under pressure.

Whether in automotive, industrial, or construction applications, rubber gaskets play an integral role in maintaining safety and efficiency.

What is a Rubber Gasket?

A rubber gasket is a flexible, compressible material used to form a seal between two surfaces that need to be joined together while preventing leakage of fluids, gases, or solids. Gaskets can come in many shapes and sizes, with rubber being the preferred material due to its high flexibility, resilience, and ability to conform to uneven surfaces.

Rubber gaskets are often used in systems that operate under varying pressure, temperature, and chemical exposure. They are made from different types of rubber compounds, each selected based on the specific needs of the application. Common types of rubber used in gaskets include neoprene, nitrile, EPDM (ethylene propylene diene monomer), silicone, and fluorocarbon (Viton).

Why Use Rubber Gaskets?

Rubber gaskets are indispensable in numerous industrial applications because they offer several key benefits:

- Leak Prevention: The primary purpose of a rubber gasket is to create a seal that prevents leaks. This is especially important in systems where fluids or gases could cause damage or pose safety risks. The flexibility of rubber allows the gasket to compress and fill in any gaps between surfaces, ensuring a leak-free connection.

- Flexibility and Compression: Unlike rigid materials, rubber gaskets can adapt to the surface irregularities of the mating parts. The rubber compresses under pressure, filling in any imperfections and providing a reliable seal. This adaptability makes rubber gaskets highly effective in preventing leaks even when surfaces are not perfectly smooth.

- Chemical Resistance: Many rubber compounds are engineered to withstand exposure to harsh chemicals, oils, and solvents. For example, nitrile rubber is commonly used in environments where fuel or oils are present, while EPDM is favored for outdoor applications due to its resistance to weathering, ozone, and UV rays.

- Temperature Tolerance: Rubber gaskets are capable of withstanding a wide range of temperatures. Certain types of rubber, such as silicone, can maintain their sealing properties even at extreme temperatures, making them ideal for applications in industries like aerospace and automotive.

- Cost-Effectiveness: Rubber gaskets are generally affordable and easy to manufacture. This makes them a cost-effective choice for sealing applications across a wide range of industries.

Types of Rubber Gaskets

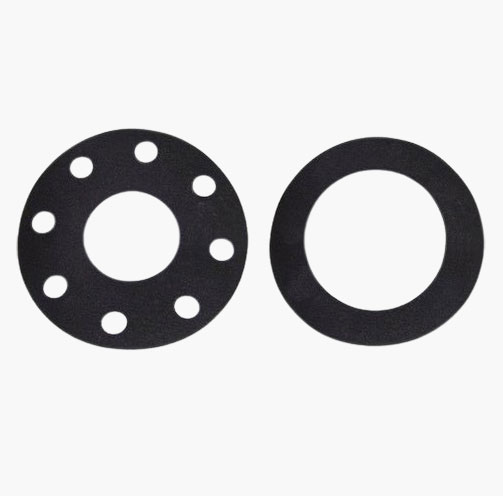

To buy click here ecofittingvalve.com/รายละเอียดสินค้า-5020-ประเก็นยาง-10k-rubber-gasket.html. Rubber gaskets come in several designs, each suited for different sealing requirements:

- Flat Gaskets: The most common type of gasket, flat rubber gaskets are simple, circular seals used to fit between two flanged surfaces. They are often used in plumbing, machinery, and automotive applications.

- O-Rings: A type of rubber gasket with a round cross-section, O-rings are used in a wide range of mechanical systems. They are most effective when compressed between two parts to create a seal. O-rings are commonly used in hydraulic and pneumatic applications.

- Cork and Rubber Gaskets: A combination of cork and rubber, these gaskets offer the benefits of both materials, providing a reliable seal for applications that require both flexibility and resistance to high temperatures.

Applications of Rubber Gaskets

Rubber gaskets are used in a variety of industries and applications, including:

- Automotive: In engines, exhaust systems, and fuel systems, rubber gaskets prevent fluid and gas leaks, ensuring the efficiency and safety of the vehicle.

- Plumbing: Rubber gaskets are commonly used in faucets, pipes, and fittings to create leak-free seals that prevent water or other liquids from escaping.

- Industrial Equipment: In manufacturing plants, rubber gaskets are essential in machinery, pumps, and compressors to maintain system pressure and prevent contamination.

- Construction: Rubber gaskets are used in windows, doors, and other building materials to ensure tight seals that improve energy efficiency and prevent moisture ingress.

Conclusion

Rubber gaskets are essential components in sealing systems across a wide array of industries. Their flexibility, resistance to chemicals and extreme temperatures, and ability to create reliable seals make them invaluable in preventing leaks and ensuring the safety and efficiency of complex systems. Whether in automotive engines, plumbing systems, or industrial machinery, rubber gaskets play a crucial role in maintaining functionality and performance.

Contact Us

Business Address : 123 Village No. 2, Soi 3, Sang Banphot, Wibun Thammarak Road Nong Mai Daeng Subdistrict Mueang Chon Buri District Chonburi 20000, Thailand

Business Phone : 084-1580786

E-mail: [email protected]

Business Website: https://ecofittingvalve.com/

Comments