If you're operating in the pharmaceutical industry, you need to count significantly on pumps for successfully creating and refining pharmaceutical drugs and medicines.

As you might currently understand, pumps allow you to especially control the circulation, transfer, mixing, and application of fluids, gases, powders, and slurries.

This article will definitely supply you with a summary of the significant sort of pumps made use of in pharmaceutical manufacturing processes and their vital applications.

Centrifugal Pumps

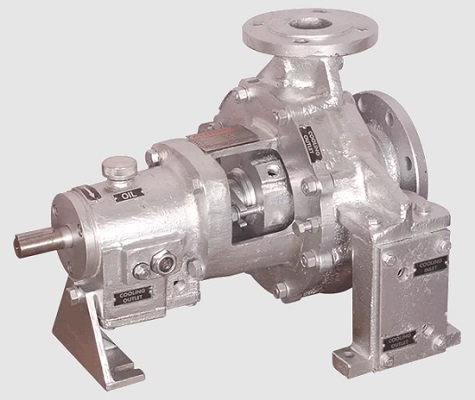

Centrifugal pumps are just one of among the most common types you will definitely find in pharmaceutical procedures. These pumps utilize an impeller to enhance fluids and accumulate a centrifugal stress that pushes the fluid out of the pump.

Centrifugal pumps are terrific for moving significant quantities of low-viscosity liquids and products. You can utilize them for applications like relocating raw materials, solvents, and completed things between vessels in your facility.

The benefits of centrifugal pumps are high flow rate, inexpensive, and extremely easy upkeep. Their main limitation is that they are not suitable for looking after high-viscosity fluids.

Some examples of centrifugal pump kinds frequently used in pharmaceutical applications are overhung pumps, axial split situation pumps, vertical inline pumps, and self priming pumps.

Lift Pumps

Lift pumps are made use of to press fluids from a lowered to higher altitude.

For the not aware, they are vertical centrifugal pumps that need to conquer the dealt with lift to move liquids uphill versus gravity. Type of lift pumps include submersible, sump, and upright generator pumps.

In pharmaceutical plants, lift pumps are used to transfer liquids in between vessels and tank at different flooring degrees. They efficiently relocate big quantities of water, solvents, and in-process fluids between decreased and high elevations.

Basically, Lift pumps offer credible transfer while minimizing shear and maintaining liquid stability.

Booster Pumps

Booster pumps increase fluid anxiety in pipes transferring liquids over long distances. They are mounted when liquids need to be pumped to remote areas at better altitudes.

In pharmaceutical plants, booster pumps keep a constant pressure for the supply of steam, water, and warm transfer liquids to various processes.

They make up for stress drops in substantial piping networks. Booster pumps also raise water stress for reliable cleaning and sanitization operations. Relied on booster pumps are vital to see to it liquids get to all points of use with appropriate pressure.

Arterial Pumps

Arterial pumps are made use of in pharmaceutical waste administration systems.

They are durable and can pump a wide array of solids, slurries, and viscous fluids. The screw layout offers an attire circulation rate and mild pumping activity.

In addition, Arterial pumps have huge pump heads to deal with solid particles without blocking. They can successfully move corrosive chemicals, wastewater, sludge, and pharmaceutical deposits over fars away.

Not simply that yet the simplicity of upkeep, sturdiness, and lengthy life span make them suitable for continual pharmaceutical waste transfer duties.

Positive Displacement Pumps

Positive displacement pumps operate in a different way than centrifugal pumps. They relocate liquids by first trapping a set amount of the fluid. Then they require that entraped amount into the outcome pipeline.

These pumps permit you to exactly manage the circulation rate regardless of back stress. This makes them optimal for metering and application applications where precision is essential.

Some sorts of positive displacement pumps utilized are piston pumps, diaphragm pumps, peristaltic pumps, and rotary lobe pumps.

The benefits of positive displacement pumps are the capacity to manage high-viscosity fluids, good suction lift, reversible flow, and high precision.

On the other hand, these pumps have some downsides too. The primary downsides are the pulsatile circulation they produce, reduced flow prices, and high prices.

Generally, positive displacement pumps are used to move viscous fluids, specifically application chemicals and ingredients, and properly meet little component amounts.

Lobe Pumps

Lobe pumps are outside gear rotating pumps used for viscous liquids like gels, and lotions.

The pumping activity is mild and perfect for shear-sensitive pharmaceuticals. They are self-priming, can run dry, and manage solids.

Usually, Lobe pumps are used for moving, application, and filling high-viscosity pharmaceuticals like lotions, syrups, and gels. They provide smooth, pulsation-free flow vital for delicate pharmaceutical products.

On the whole, Lobe pumps allow accurate, mild, and sanitary handling of viscous pharmaceutical formulas.

Diaphragm Pumps

Diaphragm pumps are made use of for destructive, unpleasant, and thick fluids.

The diaphragm supplies seclusion in between the liquid and pump internals. This allows the pumping of harmful and hazardous materials safely. They are perfect for metering and moving corrosive active ingredients in drugs.

Moreover, Diaphragm pumps additionally prevent cross-contamination and item destruction with their seal-less style. They supply low-shear, mild pumping activity important for shear-sensitive drugs and formulations.

Vacuum Pumps

In addition to centrifugal and positive displacement pumps, the pharmaceutical industry likewise utilizes vacuum pumps every now and then.

These pumps are utilized to produce suction to efficiently get rid of air, gases, or vapors from vessels, reactors, condensers, and transfer lines. In addition, they likewise aid preserve the vacuum cleaner conditions essential for numerous essential pharmaceutical processes like distillation, drying out, freeze drying out, and solvent recovery.

Common sorts of vacuum pumps are liquid ring, dry claw, rotary vane, scroll, and diaphragm pumps. The advantages of using these pumps consist of suitability for taking care of harmful, eruptive, and heat-sensitive products.

When it comes to the use situation, vacuum pumps are generally utilized for attaining vacuum in reactors, condensers, centrifuges, filtering systems, and other vessels.

Industrial Chemical Pumps

These pumps are developed for dangerous chemical transfer and processing. They provide secure containment and transfer of toxic, combustible, and reactive chemicals through their leak-proof construction.

Materials like stainless-steel, PTFE, carbon, and alloys stand up to rust from acids, caustics, and solvents. For optimal safety and efficiency, working with a reputable centrifugal chemical pump manufacturer is important.

Conclusion

Reliable and dependable pumps are crucial equipment for pharmaceutical manufacturing. As we assessed, different types like centrifugal, favorable variation, and vacuum pumps are made use of across pharmaceutical processes.

These pumps allow the risk-free, hygienic, and controlled transfer, application, mixing, and handling of pharmaceutical raw materials, intermediates, and ended up items.

That claimed, if you're searching for a trustworthy and trustworthy centrifugal multi stage pump manufacturer, SMS Pumps & Engineers can assist.

We have more than 25 years of experience supplying top notch thermic fluid pumps exactly engineered for pharmaceutical industry applications. Our knowledge ensures you obtain the best pump for your certain requirements whether it's clean and sterile transfer, accurate metering, or accomplishing a reliable vacuum cleaner.

So for your vital pharmaceutical pumping requirements, you can rely on SMS Pumps & Engineers to provide pumps that improve your efficiency and assurance.

Comments