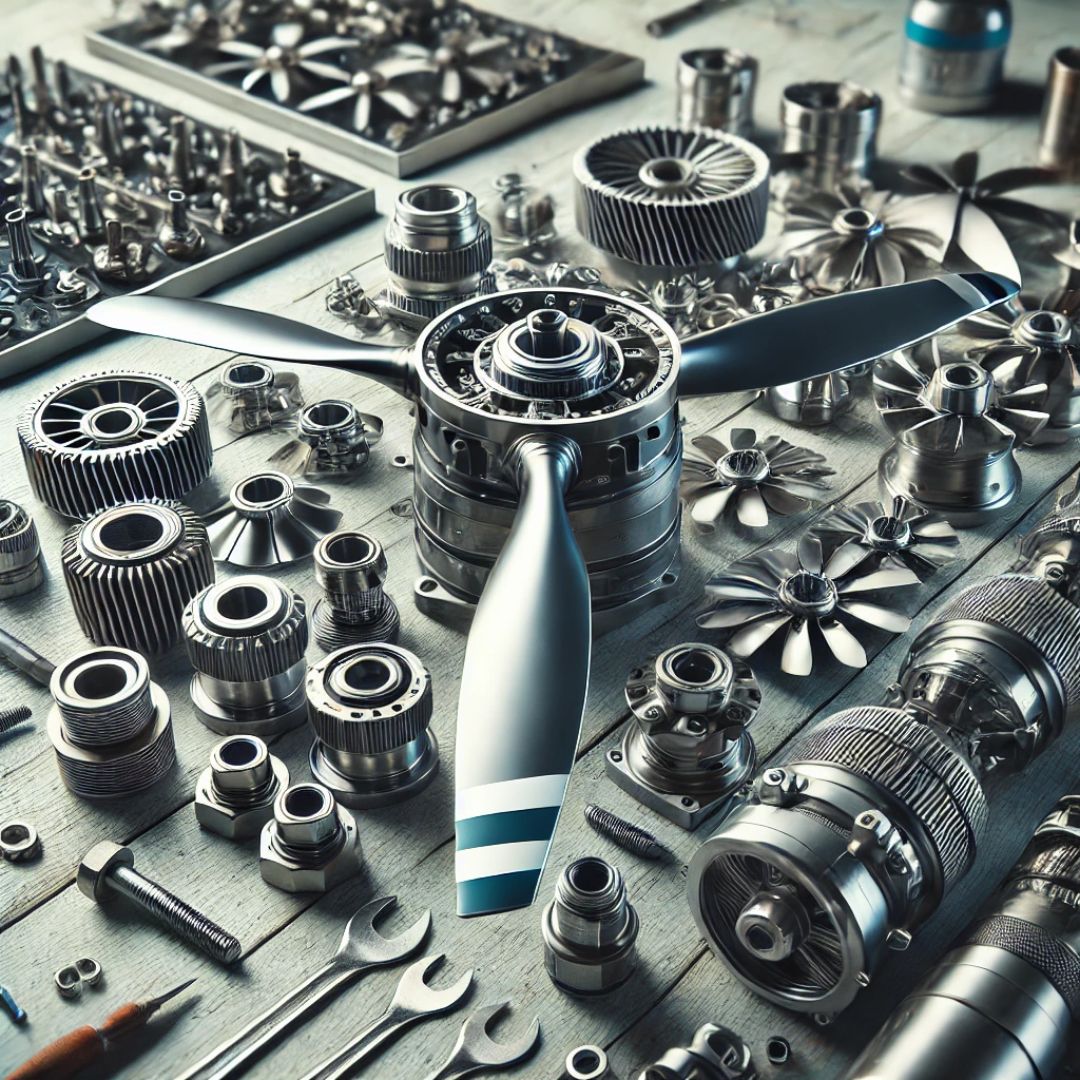

Aviation safety cannot be overemphasized, and when it comes to any aircraft, its performance and reliability highly depend on the propeller. A propeller takes engine power and turns it into thrust that lifts off, holds an altitude, and maneuvers well. To have it in an optimum operating state, every aircraft propeller parts must work at its peak. Here's an article that explains some of the basic parts of an aircraft propeller that should be considered when flying.

1. Propeller Blades

The engineering blades are one of the most recognizable parts outside an aircraft propeller. When spinning, the propeller drives forward; it must cut through the air. With the development of today's technique, thrust could then be created to give an aircraft its forward movement. They are made of lightweight materials like aluminum, composite material, and wood and are intended to withstand massive stress or fatigue during flight.

Key Considerations:

- Strength to Weight Ratio: The blades have to be lightweight but strong enough for maximum efficiency.

-Blade Shape: Blades should be aerodynamically shaped so that the air passing over the blades is in a position to provide the correct lift and thrust.

Propeller blades are prone to damage due to adverse weather. Regular inspections and maintenance are thus necessary over time.

2. Hub

The connection of the blades to the engine is achieved by a hub, which lies at the heart of the propeller assembly. It transmits the rotational power emanating from the engine to the blades. Hubs come in different designs, fixed pitch, and constant speed, according to the variety of aircraft used.

Types of Hubs:

- Fixed-Pitch Hub: The angle of the blades in a fixed-pitch propeller does not change. Therefore, design and operation are relatively straightforward.

- Constant-Speed Hub: This is a hub that will automatically change the angle that the blades are set at to optimize engine performance in varying flight conditions.

Hub Maintenance is very important because failure in the hub can cause catastrophic damage to the entire propeller.

3. Spinner

The spinner is the conical cover that encloses the central portion of the propeller assembly, usually the hub. Its primary function is to streamline airflow around the rotating hub, reduce drag, and help other related components from debris or damage during flight.

Advantages of a Spinner:

- Aerodynamics: It reduces drag by forcing air to flow cleanly around the propeller.

- Protection: It prevents foreign objects from damaging the hub and related parts.

Regular inspection is necessary to ensure that the spinner is securely attached and free from cracks or wear.

4. Governor

The propeller governor is meant to control the speed of the propeller. The governor alters the pitch angle of blades to achieve a predetermined speed for the engine and makes this even more efficient with regards to fuel for optimal performance at the various flight stages.

Functions of Propeller Governor:

- Regulation of RPM: The governor adjusts the blade angle to maintain the engine's RPM within a safe range.

-Efficiency: This is done through the regulation of blade pitch so that the engine operates under any flight condition in an efficient manner.

Constant-speed propeller aircraft will maintain the propeller at the appropriate speed during each phase of flight, through the governor.

5. Bearings

Bearings support the rotating propeller assembly, thus allowing for a smooth movement with minimal friction. These parts are usually located within the hub and allow the propeller blades to rotate without losing stability.

Types of Bearings:

- Ball Bearings: Frequently used in high-speed applications, ball bearings are used to reduce friction and increase durability.

- Roller Bearings: These types of bearings offer more support where higher load-bearing capacity is required.

Bearings should be inspected and lubricated periodically to avoid failure, which may result in improper operation or complete propeller failure.

6. Pitch Control Mechanism

The pitch control mechanism adjusts the blade angle to increase the performance of the propeller when the aircraft is under a variety of flight conditions. On fixed-pitch propellers, this angle is set during installation and cannot be changed in flight. Variable-pitch or constant-speed propellers enable the pitch to be changed as required by the different engine loads and airspeeds.

Importance of the Pitch Control Mechanism

- Fuel Efficiency: The mechanism varies the blade pitch to maintain efficiency in the running of the engine.

- Power Output: It ensures there is enough thrust at various speeds and altitudes.

The pitch control mechanism should operate correctly to avoid straining the engine or getting insufficient thrust in flight.

7. Shaft

The propeller shaft is a link that connects the engine to the hub, where the rotational force from the engine is transmitted. It has to endure a lot of torque and pressure; hence, it must be of hard material like steel or titanium. Properly maintained propeller shaft will make sure the engine consistently powers the propeller.

Maintenance Considerations:

- Lubrication: It should be regularly lubricated for easy operation and minimize wear on the shaft.

- Alignment: Proper alignment of the shaft and hub will ensure smooth running and avoid vibrations.

Final words

The propeller assembly is one of the most complex and highly specialized parts of any aircraft, and each part of it contributes to the smooth, safe, and efficient flight it is capable of. Regular maintenance, inspection, and attention to detail in each component will go a long way into performance increase and lifespan achieved with a propeller system. Any aviation professional or aircraft owner will owe it to themselves if they are well aware of the importance of each one of these critical Aircraft propeller parts in safety within the skies.

Comments