When it involves heavy-responsibility operations or tight areas, the selection of heat exchanger turns into a important aspect. Among the most efficient options to be had today is the brazed plate heat exchanger. But, is it the proper suit on your business? How does it evaluate to other varieties of warmth exchangers, especially in phrases of performance in difficult environments?

Let's dive deeper into knowledge brazed plate heat exchangers, their advantages, and how they may be a really perfect solution for annoying conditions.

What Exactly Is a Brazed Plate Heat Exchanger?

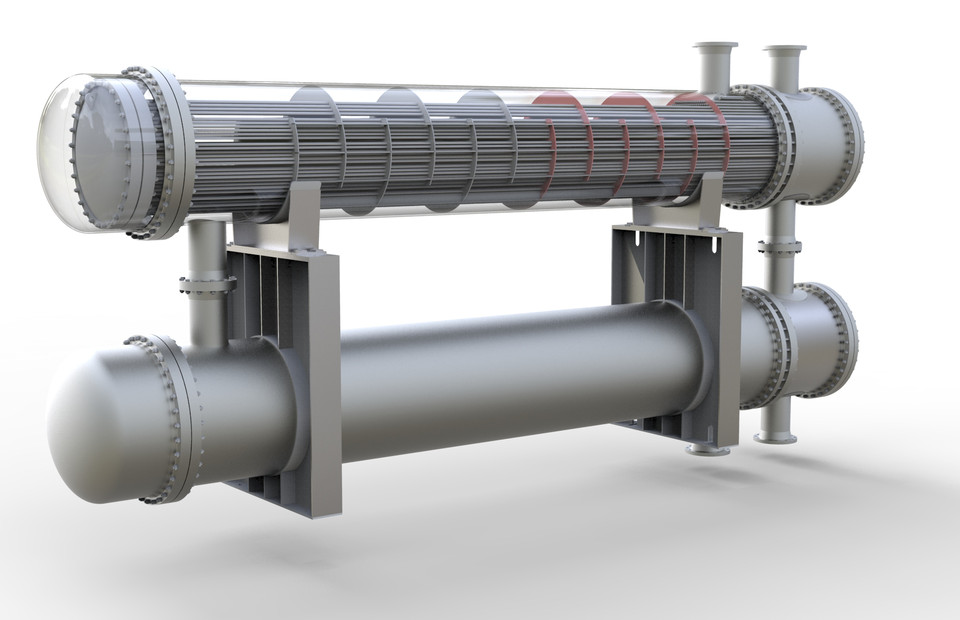

At the coronary heart of many industrial packages is the need for efficient warmness switch among two fluids. A brazed plate heat exchanger achieves this thru a sequence of chrome steel plates which might be pressed together and brazed. This sort of exchanger is compact, green, and tremendously powerful at transferring heat between fluids in structures where area is constrained or excessive warmth switch is necessary. But, what makes it precise compared to different heat exchangers?

Why Choose Brazed Plate Heat Exchangers for Heavy Use?

1. High Heat Transfer Efficiency

How does a brazed plate warmth exchanger perform in heavy-responsibility packages? The performance of those warmness exchangers lies in their layout. The narrow flow channels among the plates decorate the warmth transfer process, making it an amazing preference for industries like HVAC, chemical processing, and meals manufacturing. The improved surface place and turbulent flow created in the plates permit the warmth exchange to show up fast and correctly.

2. Compact and Space-Saving Design

What when you have limited space for installing a heat exchanger? One of the maximum sizable benefits of brazed plate warmness exchangers is their compact design. Unlike traditional shell-and-tube warmth exchangers, which can soak up extensive space, brazed plate gadgets are small and can be installed in areas with tight areas. Their ability to address excessive warmth switch within a smaller footprint makes them a super choice for industries where area is at a premium.

3. Durability in Harsh Environments

Can brazed plate warmth exchangers face up to heavy use and vicious conditions? Absolutely. The layout of these exchangers uses awesome materials, along with chrome steel, which gives them electricity and resistance to corrosion. Whether in chemical flora, refineries, or electricity vegetation, these exchangers can cope with the needs of tough business environments. Moreover, the brazed joints are designed to be leak-proof, including an additional layer of security in critical packages.

4. Reduced Maintenance Needs

What about preservation? A main concern with heavy-obligation device is the time and cost required for preservation. However, brazed plate heat exchangers require minimum upkeep because of their long lasting layout and green operation. With fewer components and no gaskets, the chance of leakage is decreased, ensuing in fewer repairs and much less downtime. This can save corporations both time and money in the end.

5. Energy Efficiency

In an technology of rising energy prices, how do brazed plate warmness exchangers make contributions to power savings? Their green warmness transfer abilties imply that less energy is needed to attain the identical stage of warmth trade, reducing the overall electricity consumption of the gadget. This performance is mainly useful for companies looking to decrease operating prices and enhance sustainability.

Where Are Brazed Plate Heat Exchangers Used?

1. Chemical Processing

Can brazed plate warmness exchangers cope with the precise wishes of chemical processing? In industries like chemical manufacturing, retaining the best temperature is crucial for safety and efficiency. Brazed plate warmness exchangers offer rapid warmth transfer whilst presenting the flexibility to manipulate diverse fluid temperatures, making them best for chemical reactors, distillation columns, and other chemical processing gadgets.

2. HVAC Systems

Why are brazed plate warmth exchangers perfect for HVAC applications? HVAC structures, in particular in large business and industrial homes, require green heat transfer to keep snug indoor temperatures. The compact size of brazed plate warmness exchangers makes them a remarkable choice for these systems, wherein area is frequently confined. Moreover, the low-maintenance layout guarantees reliable performance even in disturbing situations.

3. Food and Beverage

How do brazed plate warmness exchangers gain the food and beverage enterprise? In this enterprise, retaining precise temperature manage is important. Whether it is for pasteurization, sterilization, or chilling methods, brazed plate warmth exchangers provide the performance and compact layout had to meet the stringent necessities of meals processing flowers. Their capacity to deal with excessive-float prices and ranging temperatures makes them integral in those programs.

4. Power Generation

Are brazed plate warmth exchangers appropriate for energy era vegetation? In power plants, dealing with the temperature of the operating fluids is essential for most useful electricity manufacturing. Brazed plate warmness exchangers excel in these environments because they could effectively take care of the excessive temperatures and pressures located in steam and cooling structures. Their compact layout additionally makes them best for the tight spaces frequently determined in energy flora.

How Do Nash Liquid Ring Vacuum Pumps Compare?

While brazed plate warmth exchangers are recognised for his or her heat transfer efficiency, many industries additionally depend upon different kinds of device for unique functions. For example, Nash liquid ring vacuum pumps play a essential function in developing a vacuum within business systems. These pumps are used to address gases and vapors, assisting to keep most reliable running situations in industries together with pharmaceuticals, meals processing, and chemical manufacturing.

But, how do they examine to brazed plate heat exchangers? While both are important components in business strategies, they serve different functions. While brazed plate warmth exchangers consciousness on green warmness switch, Nash liquid ring vacuum pumps cognizance on maintaining pressure and evacuating gases. In many cases, those components may fit together in a system to maintain both temperature and strain controls.

How Do You Choose the Right Heat Exchanger for Your Needs?

1. Application

What elements have to have an effect on your decision whilst deciding on a warmth exchanger? Understanding your application's requirements is prime. If you want a warmth exchanger that can cope with heavy use in a good area while presenting amazing heat switch efficiency, a brazed plate warmness exchanger might be your nice wager.

2. Space and Size

Do you've got a small set up region? Brazed plate heat exchangers are compact, so if area is a constraint, this sort of exchanger is a notable choice.

3. Maintenance

How a good deal downtime can your operation have enough money? Brazed plate heat exchangers are designed to require minimal upkeep, making them best for operations wherein reliability is a ought to.

4. Energy Efficiency

Are you aiming to lessen power intake? With their excessive heat switch performance, brazed plate warmth exchangers can help reduce your strength bills, making them a smart funding for power-conscious agencies.

Conclusion: Why Brazed Plate Heat Exchangers are the Smart Choice

So, are brazed plate heat exchanger the right answer on your heavy-use or area-confined applications? With their green layout, sturdiness, low maintenance requirements, and strength-saving ability, those exchangers provide several blessings across numerous industries. Whether you are working in HVAC, meals and beverage, chemical processing, or strength era, the brazed plate warmness exchanger can provide the overall performance you need in tight spaces or demanding situations. When paired with equipment like Nash liquid ring vacuum pumps, those exchangers assist hold most advantageous gadget overall performance, ensuring your operations run easily and successfully.

In the end, the compact and effective brazed plate warmth exchanger can also just be the flexible answer your business desires!

.jpg)

Comments