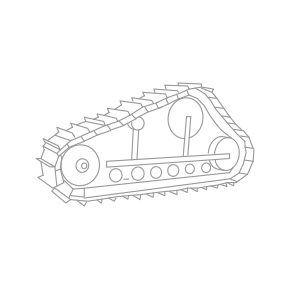

Caterpillar bottom rollers play a crucial role in the efficiency and performance of heavy machinery, particularly in bulldozers and excavators. These rollers are essential components of the undercarriage system, ensuring smooth operation on rough and uneven surfaces. Caterpillar bottom rollers are designed to withstand heavy loads and extreme conditions, offering optimal support to the tracks. Regular maintenance and timely replacement of these rollers are critical to ensure the longevity and smooth functioning of machinery.

How Caterpillar Bottom Rollers Contribute to Efficiency

The primary function of Caterpillar bottom rollers is to support the weight of the dozer and maintain track tension, which allows for efficient operation in tough terrains. These rollers help to distribute the weight evenly, preventing undue stress on the tracks. When in good condition, they contribute to smoother operations, reducing wear and tear on other components. Without functioning bottom rollers, the undercarriage would struggle with excessive friction, resulting in lower productivity and higher maintenance costs.

When to Replace Caterpillar Bottom Rollers

Over time, Caterpillar bottom rollers may experience wear and tear due to constant exposure to harsh working environments. Signs of wear can include noticeable damage, cracks, or uneven wear patterns. If not addressed, these issues can lead to decreased efficiency and costly repairs. It’s important for operators to regularly inspect the rollers and replace them when necessary. Ensuring the bottom rollers are in good condition is crucial for maximizing the lifespan of the undercarriage and the overall performance of the machine.

Track Chain for Caterpillar Dozer: Essential Component for Performance

The track chain for Caterpillar dozer is another vital part of the undercarriage system. These chains provide the necessary traction for the dozer to operate effectively on various terrains, from soft dirt to rocky surfaces. The track chain connects the different parts of the undercarriage and allows the dozer to move smoothly while supporting the weight of the machine. A well-maintained track chain ensures maximum efficiency and helps to extend the lifespan of the equipment.

Choosing the Right Track Chain for Caterpillar Dozer

When purchasing a track chain for Caterpillar dozer, it’s essential to choose a high-quality replacement that matches the specifications of the original equipment. Compatibility with the machine model and terrain conditions is crucial for ensuring the dozer’s optimal performance. High-quality track chains are designed for durability and can withstand rough working conditions, providing reliable service over extended periods. Selecting the right track chain can prevent unnecessary wear and tear, improving the overall productivity of the machine.

Maintaining and Replacing Track Chain for Caterpillar Dozer

Regular maintenance of the track chain for Caterpillar dozer is essential for preventing premature wear and maintaining efficiency. This includes checking for proper tension, inspecting for damage or wear, and ensuring all components are functioning smoothly. If the track chain is worn or damaged beyond repair, it should be replaced immediately to avoid further complications. By replacing the track chain on time and maintaining it properly, operators can ensure their dozers continue to perform at peak efficiency and remain reliable for long-term use.

In conclusion, both Caterpillar bottom rollers and track chain for Caterpillar dozer are essential components for ensuring optimal performance and longevity of the machinery. Regular maintenance and timely replacements can significantly enhance the efficiency and lifespan of the dozer. For top-quality replacement parts, visit tracksnteeth.com, where a wide range of durable parts for Caterpillar dozers is available to meet all your equipment needs.

For a better understanding of this topic, visit our website.

Comments