Stainless Steel 310 Buttweld Fittings are a reliable solution for industrial piping systems that require strength, durability, & resistance to extreme environments. Combining robustness with exceptional performance under high temperatures, these fittings are ideal for a variety of industries such as oil and gas, chemical processing, and power generation. This guide explores the features, benefits, & applications of Stainless Steel 310 Buttweld Fittings while also integrating comparisons with high-performance materials like Super Duplex 2507 Pipe & C276 Pipe Fittings.

What are Stainless Steel 310 Buttweld Fittings?

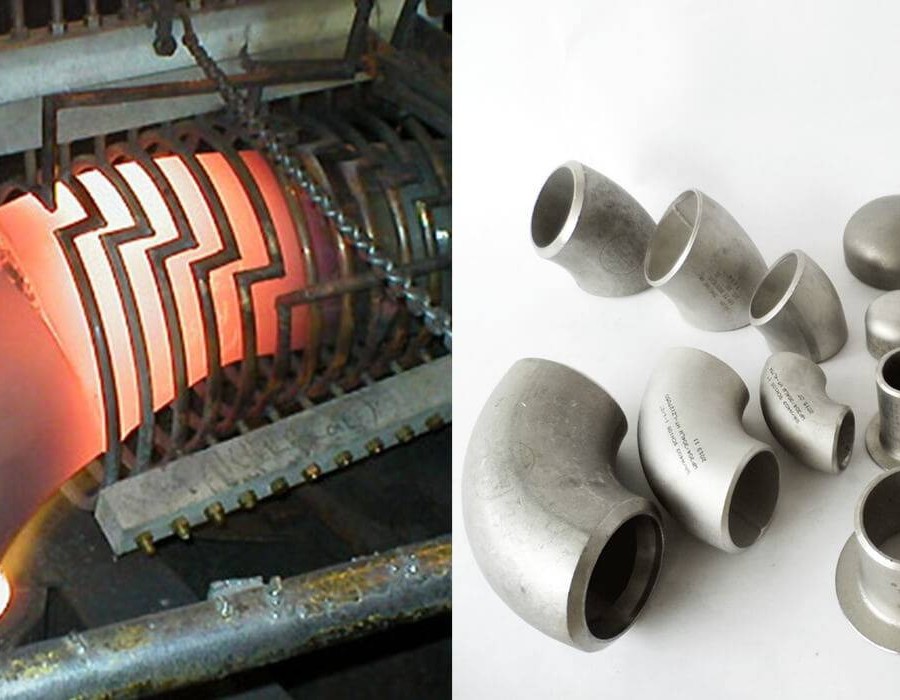

Stainless Steel 310 is a high-temperature resistant alloy made of 25% chromium and 20% nickel, which provides excellent resistance to oxidation and corrosion. Buttweld fittings made from this grade are designed to connect pipes seamlessly, ensuring smooth flow and maintaining the integrity of piping systems.

The buttweld design offers a permanent, leak-proof joint, making these fittings perfect for pipelines that operate in extreme conditions. Their ability to withstand both high thermal stress and corrosive environments makes them a preferred choice for industrial piping systems.

Key Characteristics of Stainless Steel 310

- High-Temperature Resistance: Performs effectively in environments up to 2100°F (1150°C).

- Corrosion and Oxidation Resistance: Protects against scaling and oxidation in highly acidic or corrosive environments.

- Mechanical Strength: Handles high pressure and heavy loads with ease.

- Thermal Stability: Maintains structural stability even with significant temperature variations.

With these properties, SS 310 buttweld fittings have gained widespread applications across demanding industries.

Key Features of SS 310 Buttweld Fittings

1. Resistance to High Temperatures

Stainless Steel 310 is specially designed for high-heat applications, such as furnaces, thermal plants, and heat exchangers. It retains its strength and form even at elevated temperatures, making it highly efficient for industrial use.

2. Corrosion Resistance

The high chromium and nickel content in SS 310 allows it to resist oxidation, pitting, and crevice corrosion. This property ensures long-term performance in applications where other metals might fail.

3. Leak-Proof Connections

The buttweld design creates a smooth, seamless joint that eliminates the risk of leaks. This feature is critical for systems dealing with liquids or gases at high pressure or temperature.

4. Durability and Longevity

The robust mechanical properties of Stainless Steel 310 extend the lifespan of piping systems, providing a cost-effective and low-maintenance solution.

5. Versatility in Applications

These fittings can be easily welded and customized to fit various industrial requirements, making them highly versatile for varied piping configurations.

These features enable Stainless Steel 310 Buttweld Fittings to enhance the efficiency and safety of piping systems across industries.

Applications of Stainless Steel 310 Buttweld Fittings

1. Oil and Gas Industry

The high-temperature resistance and ability to handle corrosive environments make Stainless Steel 310 the perfect choice for refineries, pipelines, and offshore platforms. These fittings provide durability under extreme conditions, ensuring smooth transportation of oil & gas.

2. Chemical Processing

Chemical plants often involve corrosive chemicals and high-pressure systems. SS 310 Buttweld Fittings excel in handling acidic and oxidizing solutions, reducing the risk of material degradation.

3. Heat Exchangers and Furnaces

The thermal stability of these fittings makes them invaluable in heat exchangers, boilers, and furnaces. They can efficiently handle the fluctuating temperatures and stresses in such systems.

4. Power Generation

From nuclear power plants to thermal plants, Stainless Steel 310’s ability to resist extreme heat and corrosive fluids makes it essential for steam piping and other high-performance systems.

5. Petrochemical Industry

These fittings are ideal for petrochemical plants, where conditions involve a combination of high pressure, temperature, and exposure to hydrocarbons.

6. General Industrial Applications

Stainless Steel 310 Buttweld Fittings are also used in general industrial applications, such as food processing plants and water treatment facilities, where hygiene and durability are critical.

These applications demonstrate the adaptability and importance of these fittings across industries.

Stainless Steel 310 vs. Super Duplex 2507 & C276 Pipe Fittings

While SS 310 Buttweld Fittings provide exceptional performance, other materials such as Super Duplex 2507 Pipe & C276 Pipe Fittings are often used for specific applications.

- Super Duplex 2507 Pipe: Known for its twice-as-strong mechanical properties, Super Duplex 2507 is more suited to high-pressure systems and marine applications. It performs extremely well against chloride-induced corrosion, making it a popular choice for offshore platforms and desalination plants.

- C276 Pipe Fittings: Made from Hastelloy C276, these fittings are specifically designed for extreme chemical resistance. They are ideal for systems handling hydrochloric acid, wet chlorine gas, or sulfuric acid, often used in chemical tanks and reactors.

Why Choose SS 310 Buttweld Fittings?

When selecting materials for your industrial piping systems, Stainless Steel 310 provides a reliable and cost-effective solution. Here’s why:

- Versatility: Suitable for a wide variety of industries, from chemical processing to power generation.

- Reliability: Leak-proof connections ensure safe and efficient operation in the most demanding environments.

- Durability: High resistance to heat, oxidation, and pressure results in a longer lifespan.

- Cost-Effective: Stainless Steel 310 is relatively affordable compared to other high-performance alloys, making it a practical investment.

Final Thoughts

Stainless Steel 310 Buttweld Fittings are indispensable in industries that demand high heat resistance, durability, and corrosion protection. Their ability to handle extreme conditions makes them a trusted choice for chemical plants, oil refineries, power generation facilities, and more. Neo Impex Stainless Pvt. Ltd. ensures these fittings meet the highest quality standards, offering features like seamless connectivity, thermal stability, and robust mechanical strength. These qualities make Stainless Steel 310 Buttweld Fittings the ideal solution for industrial piping needs, delivering unmatched performance and reliability.

Comments