Introduction

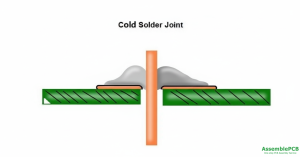

Cold solder joints are also known as pseudo-soldering. They are a bad solder joint that is produced during PCBA or SMT. The solder joint is unreliable because it lacks good intermetallic compound (IMC) formation. This can cause serious line failures.

1. Cold Solder Joint and Why it Should Be Avoided

A cold solder joint forms when solder fails to melt completely (preventing proper joint formation); it has a rough, rigid, uneven surface, and is prone to cracking, failure, and increased electrical resistance–ultimately reducing the reliability of electronic assemblies.

Symptoms of Cold Solder Joints:

- dull or grainy joint

- lumpy or blob-like joint

- weak or brittle connection

- circular cracks

- bulging solder point

- concave-shaped joint

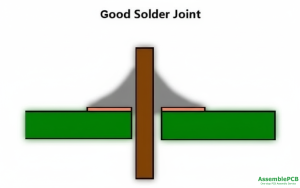

Good solder joint features:

- cone-shaped fillet joint

- volcano shape

- shiny solder

- 45 °C abrupt slope

Solder should be angled 40-70 degrees away from the pin and surface of through-hole components. Heat the soldering gun to 15°C over the melting point of the solder and maintain the temperature for 45 seconds.

Surface-mounted components have no pins on the opposite side of the board. This is because they are soldered using a different process called reflow. They won’t have a concave form.

Cold solder joints are caused by a variety of soldering problems.

Disturbed Joint: When there is a disruption at the joint, before the solder paste has hardened.

Overheated Joint: This occurs when the solder does not melt correctly, which causes the flux to overheat on the board.

Insufficient Wetting: happens when the board or pin is burnt more than others.

Comments