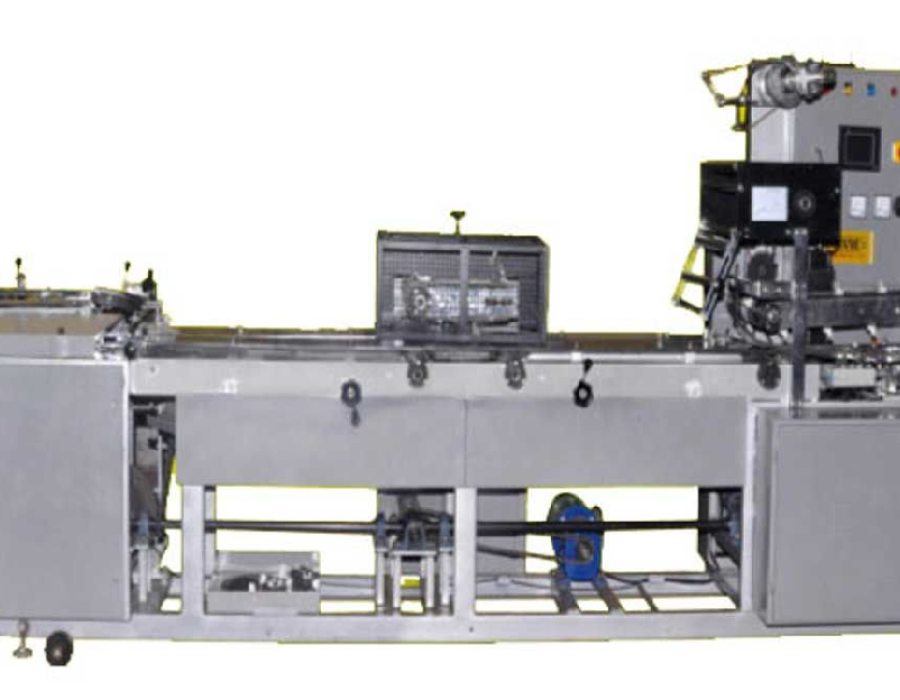

A biscuit and soap wrapping packaging machine is a specialized equipment used in the food and personal care industries to efficiently package biscuits and soaps. These machines are designed to wrap individual products in a protective covering, ensuring hygiene, freshness, and attractive presentation. Here's how a biscuit and soap wrapping packaging machine typically works:

- Product Feeding: The process begins with feeding the biscuits or soaps into the packaging machine. This can be done manually or automatically, depending on the machine's configuration. Automatic machines often have a conveyor belt or feeding mechanism that moves the products into the packaging area.

- Film Unwinding: The packaging material, usually a roll of plastic film or foil, is unwound and fed into the machine. The film is chosen based on the product's requirements, such as barrier properties, visibility, and branding needs.

- Product Alignment: Once the product and packaging material are ready, the machine aligns the products in the desired configuration for wrapping. This can include arranging biscuits in rows or positioning soaps for efficient packaging.

- Wrapping: The packaging machine then wraps the individual biscuits or soaps with the packaging material. This can be done using various wrapping techniques, such as flow wrapping or shrink wrapping, depending on the type of machine and product being packaged.

- Sealing: After wrapping, the machine seals the edges of the packaging material to create a secure and airtight seal around the product. This sealing process helps maintain product freshness and prevents contamination during storage and transportation.

- Cutting and Trimming: Once sealed, the machine cuts the wrapped products into individual units, if necessary. It may also trim excess packaging material to create a neat and professional appearance.

- Optional Features: Some advanced packaging machines may include additional features such as labeling, date coding, or inserting promotional materials into the packaging. These features enhance product traceability, marketing, and consumer engagement.

- Quality Control: Throughout the packaging process, the machine may incorporate quality control measures to ensure that each wrapped product meets specified standards. This can include checking for proper sealing, accurate labeling, and consistent packaging appearance.

- Finished Product: After completing the wrapping and quality control steps, the packaged biscuits or soaps are discharged from the machine, ready for storage, distribution, or retail display.

In conclusion, a biscuit and soap wrapping packaging machine automates the process of wrapping individual products in protective packaging material, ensuring product hygiene, freshness, and visual appeal. These machines play a crucial role in the efficient and standardized packaging of biscuits, soaps, and similar consumer goods.

Comments