The composite rollers market is poised for substantial growth in 2024, driven by advancements in materials, increasing demand across industries, and the push for lightweight, durable solutions. Composite rollers, made from carbon fiber, fiberglass, or other advanced composites, offer significant advantages over traditional metal rollers, such as reduced weight, corrosion resistance, and lower maintenance costs. However, the market also faces a set of challenges that need to be addressed for sustained growth. This article explores the key challenges and opportunities shaping the composite rollers market in 2024.

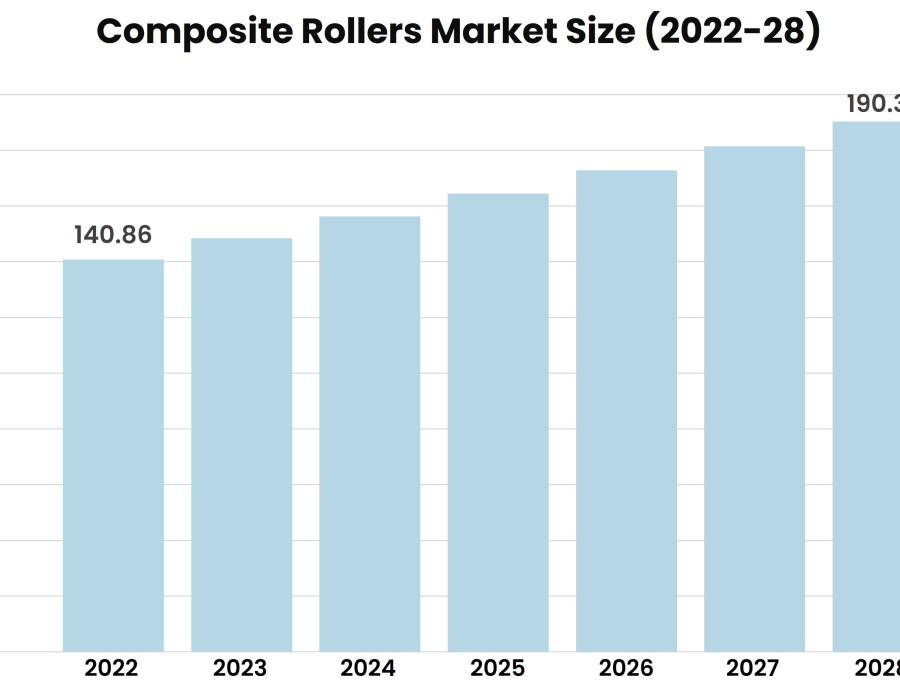

According to Stratview Research, the composite rollers market was estimated at USD 140.86 million in 2022 and is likely to grow at a CAGR of 5.09% during 2023-2028 to reach USD 190.39 million in 2028.

Opportunities in the Composite Rollers Market

- Demand for Lightweight Solutions One of the primary opportunities in the composite rollers market lies in the growing demand for lightweight materials across industries. Composite rollers are significantly lighter than traditional steel rollers, making them ideal for applications where reducing overall system weight is critical. This advantage is particularly important in sectors like mining, paper & pulp, and material handling, where weight reduction can lead to energy savings, reduced wear on machinery, and improved efficiency.

- Technological Advancements Innovations in composite materials, including the use of carbon fiber and advanced resins, are opening up new possibilities for composite rollers. These materials offer superior strength-to-weight ratios and durability, expanding their applications in high-stress environments. Moreover, advancements in manufacturing techniques, such as automated winding and molding, are making composite rollers more cost-effective, increasing their market appeal.

- Sustainability and Energy Efficiency As industries focus on reducing their carbon footprint and improving sustainability, composite rollers offer an eco-friendly alternative to metal rollers. Their lightweight design requires less energy to operate, leading to greater energy efficiency in processes like conveying and material handling. Additionally, the longer lifespan and lower maintenance requirements of composite rollers contribute to reducing waste and resource consumption.

Challenges in the Composite Rollers Market

- High Initial Costs Despite their long-term benefits, the initial cost of composite rollers remains higher than traditional metal rollers. This can deter some industries from making the switch, particularly in cost-sensitive sectors. To overcome this, manufacturers must focus on reducing production costs through economies of scale and promoting the long-term cost savings associated with composite rollers, such as reduced maintenance and downtime.

- Limited Awareness and Adoption While composite rollers offer numerous advantages, some industries remain hesitant to adopt them due to limited awareness or resistance to change. Educating key decision-makers on the benefits of composite rollers, such as increased durability, corrosion resistance, and energy efficiency, will be crucial to expanding market penetration.

Conclusion

In 2024, the composite rollers market is set to experience both challenges and opportunities. By addressing the cost and awareness issues and capitalizing on the growing demand for lightweight, sustainable solutions, manufacturers can position themselves for long-term success in this evolving market. The future of composite rollers looks promising, with advancements in materials and technology poised to drive significant growth in the coming years.

Comments