Strip brushes are one of the most versatile brush types that are used in many industries for cleaning, conveying, sealing, and many other purposes. They have a base which can be wood, plastic or metal and have filaments or strips of materials like nylon, polypropylene or boar bristles on the base. Due to this flexibility, strip brushes are suitable for applications that need filaments to nestle against curved, angled, or uneven surfaces. Let me introduce strip brushes and describe its components and materials, types and profiles, and typical areas of usage in various industries.

What Are Strip Brushes?

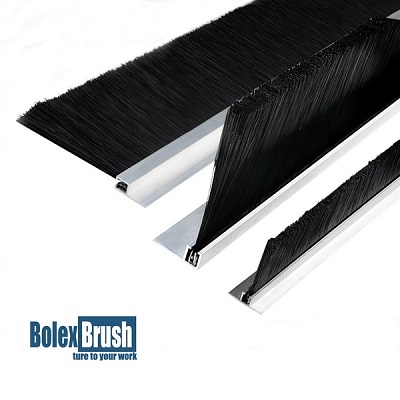

A strip brush can be described in terms of the base material to which flexible strips or filaments are fitted along the length of the brush. The base, also known as a substrate, serves as the foundation of the structure. It is the attached strips that give the brushing, wiping, sealing, conduction or other function that is required for the specific application. This is because the strips are placed evenly in a manner that does not compromise the contact or efficiency of the brush. The terms that are used with reference to this linear arrangement of bristles or strips are the strip brush or the smoother/wiper strip.

Remove brush components and materials

Strip brushes feature three main components:

Base/Substrate: Normally wooden, plastic, or metallic. Aids in connecting the flexible strips for easy adjustment on the vehicles being followed.

Strips/Filaments: Products like nylon, polypropylene, boar hair, felt, fabrics etc. These strips make contact for cleaning, wiping, etc…

Attachment Method: They can be attached to the base through stapling, gluing, inserting, crimping or fusing. The method involves the use of materials and brush.

Some of the typical cross-sectional shapes of strip brushes include rectangular, convex and concave cross sections. The base thickness, strip length as well as the material of the strip and size of the brush strips can be adjusted to meet the needs of a particular application.

These are the following major types of strip brushes:

There are several main types of strip brushes, differentiated by their materials and intended uses:

- Cleaning/Sweeping Brushes: Flexible for debris, particle, dust removal by staple-set boar bristles, or synthetic filaments.

- Sealing/Wiping Brushes: Flexible plastic, nylon or urethane strips which expand to cover gaps or wipe the surfaces.

- Conductive Brushes: In electrostatic applications, carbon or metal filaments convey electric current.

- Material Handling Brushes: Position using angled or profiled nylon/plastic strips to assist in guiding or positioning or steering materials.

Common Industrial Applications

Strip brushes have many uses across general and specialty industry sectors:

- Agriculture & Food Processing: Clear washed harvested produce, clean the surfaces and equipment used in filling, place sealed sterilized containers.

- Automotive Manufacturing: Scrape stamping die debris, electrical bonding, clean windshields/ windows

- Aerospace: Reduce or remove FOD (foreign object debris), direct hydraulic fluids, discharge static

- Printing Industry: Align paper guides, cleaning rollers and blankets, sweeping cut paper / labels

- Woodworking: clean up sawdust, application of glue, sanding wood smooth

- Machine & Component Manufacturing: Seal machined parts, wipe cables/housings, and discharge the static electricity.

- Medical & Clean rooms: Particle removal by wiping on precision equipment, clean room garments.

Conclusion

Strip brushes can offer specific performance characteristics coming from their construction of having flexible strips emanating from the base substrate. This enables them to hug uneven and angled surfaces like no other solid brushes can do it. Strip brushes can be utilized for a wide variety of cleaning, sealing, wiping, and material handling applications depending on the selection and application of the materials to be used in manufacturing the strip brushes. Their uses encompass delicate instruments used in the surgery, manufacturing industries, and industries that deal with heavy machinery. Strip brushes are widely utilized across industries as an indispensable part of brushes, and will only enhance industrial processes further in the future.

Author’s Bio

Bolex Industrial Brushes Co., Ltd is a company located in Guangzhou and is a manufacturer of a wide range of industrial brushes. We were established in 2011, we have our committed workforce and we use sophisticated tools and technology to manufacture the brushes. Our range of products comprises twisted wire brushes, tube cleaning brushes, spiral brushes, Strip Brushes, and others. We always pursue the improvement of our manufacturing techniques and the creation of new industrial brush products.

Comments