In the early nineteenth century, rolling mill manufacturing was the only method used to make stainless steel pipes and cylinders for industrial purposes. Instead the rolled strips of the whole sheet were shaped into a small circular cross-section mostly with the aid of funneling rolls.

Fortunately, with the advent of growth and technology, different processes have come into being for the manufacture of stainless steel pipes and Buttweld Pipe Fittings Manufacturers in India. Nowadays those, stainless steel pipes and otherwise tubes are made by continuous tube mills using the multi-torch biologically inert tungsten gas. Perhaps the heavy metal or even forge welding method of the filler material is not used in this procedure.

Stainless steel Pipe and otherwise Tube Production Process

Definition of the method of tube mill:

* Folding and welding

In the first instance, the made of stainless steel strips are indeed designed to undergo multiple consistency tests and are shaved at the ends. Because they just are then probably fed again to the stainless steel Flanges Manufacturers in India. The strips move out through the total number of even more rollers according to the size required. Even in the tube factory, the strip is progressively turned into another tubular shape. The scraps and inside of the welding bead are indeed removed instantaneously mostly by the Tibo unit. A420 WPL6 Fittings and otherwise tubes are shaped in this manner.

* Washing and heating stages

Again the rolled made of stainless steel pipes thus developed are cut to the necessary lengths, based on the industrial demand. Copper Pipe Fittings Manufacturers in India has been doing a great work. All these stainless steel pipes and otherwise tubes are then cleaned to remove the soil. In addition, these rolling pipes and tubes are heat treated to eliminate tension that can occur due instead to welding and shaping processes. Heat therapy is applied to a constantly rolling hearth blast furnace. The blast furnace is packed with surface temperature recorders and otherwise controls. Just after the heat treatment process, perhaps the Super Duplex Flanges and otherwise pipes are indeed straightened and pickled to remove scales first from the floor.

* Cold-draw method

In certain cases, the appropriate size cannot be collected directly from the mill. The freezing cold operation procedure can then be used to achieve the correct size of Astm A182 F9. Again the tubes or even pipes are coated mostly with oxalic and otherwise soap and water solution somewhere in the freezing cold drawing process. Copper Nickel Fittings Manufacturers also play a huge role in this industry. Even this solution serves as a lubricant to minimize friction during freezing cold drawing activity. During the freezing cold drawing process, again the tube or otherwise pipe is actually drawn out over the bench to make just using Die plugs.

* Phase of completion

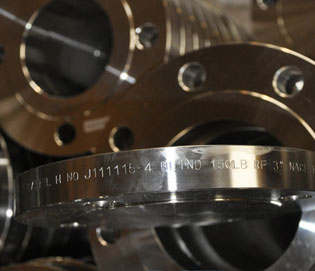

The steel tube or perhaps even ss pipe is then constantly subjected to washing, heat treatment, pickling and otherwise straightening. The computerized ink jet branding machine which is used to mark down the nearly finished steel pipes or tubing. The steel pipe or even tube shall be labeled with the grade level of the item, the duration, the heating number and therefore the stamp of the whole third party inspection prior to the transition to the stainless steel pipe's exporters. Certain tests and quality checks shall be carried out on the stainless steel blind flanges or the pipes made by them. This process is accompanied by proper packaging and dispatching. Numerous uses of stainless steel pipes are available, for which these pipes and otherwise tubes are subsequently used.

Comments