In today's rapidly advancing industries, the demand for lightweight, durable, and complex composite structures is constantly rising. These structures, which are integral to sectors such as aerospace, automotive, and construction, require a manufacturing process that ensures precision, strength, and consistency. One such method that has gained prominence for creating high-performance composites is Resin Transfer Moulding (RTM). This advanced technique allows manufacturers to produce intricate components with superior mechanical properties, all while maintaining cost efficiency over the long term. Companies like Datum Advanced Composites in Kanpur are leveraging this technology to deliver cutting-edge solutions in the field of lightweight composite products.

Understanding Resin Transfer Moulding

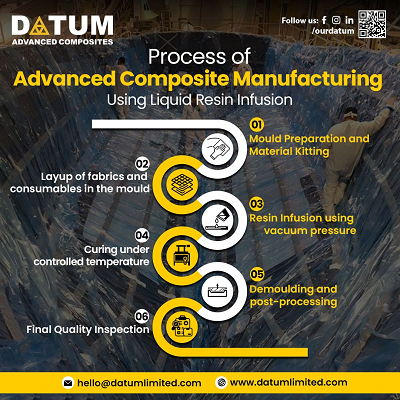

Resin Transfer Moulding is a highly effective process in which dry reinforcement fabrics, such as glass or carbon fibers, are placed into a mold cavity. These fabrics can either be layered individually or preformed, depending on the specific requirements of the component being manufactured. Afterward, a second mold tool is clamped over the first to create a sealed cavity. In the next stage, resin is injected into the mold, filling the cavity and impregnating the reinforcement fabrics. Sometimes, vacuum pressure is applied to assist in drawing the resin through the materials, ensuring complete saturation.

The curing of the resin can occur at either ambient or elevated temperatures, depending on the resin's properties and the specific application. The end result is a strong, durable composite with molded surface finishes on both sides of the component, making it highly suited for aesthetic as well as functional applications.

Why Resin Transfer Moulding is Ideal for Complex Structures

One of the key advantages of Resin Transfer Moulding is its ability to produce complex shapes and intricate geometries. For industries like aerospace and automotive, where weight reduction is critical without compromising on strength, RTM provides a solution that allows for the creation of lightweight components with high structural integrity.

The precision offered by RTM makes it easier for manufacturers like us to create parts that meet tight tolerances, ensuring a consistent final product. This is especially important when producing components that must endure extreme conditions, such as high stress, temperature variations, or exposure to corrosive environments.

Durability and Strength in Composite Structures

Another significant advantage of Resin Transfer Moulding is the durability and strength it imparts to composite structures. The process ensures that the reinforcement fibers are uniformly distributed within the resin, resulting in a well-bonded, robust composite. This uniform distribution contributes to the overall mechanical strength of the part, making it capable of withstanding heavy loads and enduring long-term wear and tear.

We specialize in producing advanced composite products that meet the highest durability standards. By employing the RTM process, they are able to manufacture components that not only meet the specific needs of their clients but also ensure longevity and performance. Their expertise in using high-quality fibers and resins further enhances the properties of the final product, ensuring it can perform in demanding applications.

Applications of Resin Transfer Moulding

Resin Transfer Moulding is widely used in several industries due to its versatility and reliability. Some of the most common applications include:

- Aerospace: The aerospace industry relies on RTM for producing lightweight yet strong components that reduce the overall weight of aircraft, improving fuel efficiency and performance. Wing panels, fuselage sections, and interior components are often manufactured using RTM.

- Automotive: Automotive manufacturer’s uses RTM to produce durable and lightweight parts such as body panels, dashboards, and structural components. This helps improve fuel efficiency while maintaining vehicle safety and performance.

- Construction: In the construction industry, RTM is used to create architectural elements that are both aesthetically pleasing and structurally sound. Components such as panels, beams, and façade elements benefit from the precision and strength offered by RTM.

- Marine: The marine industry utilizes RTM to produce components like hulls, decks, and other structural parts that must withstand harsh environmental conditions. RTM ensures these parts are both strong and lightweight, making them ideal for marine applications.

The Role of Datum Advanced Composites in RTM

Datum Advanced Composites, based in Kanpur, has positioned itself as a leader in the field of advanced composite manufacturing by utilizing Resin Transfer Moulding. Their expertise in RTM allows them to deliver high-quality composite solutions that cater to the needs of industries requiring lightweight, durable, and complex components.

What sets us apart is their commitment to innovation and quality. Their state-of-the-art facilities are equipped with the latest RTM technology, enabling them to produce components with high precision and superior surface finishes. Their engineering team works closely with clients to develop customized solutions that meet specific design and performance requirements.

Additionally, we emphasize the importance of sustainable manufacturing practices. By optimizing the RTM process, they are able to minimize waste and ensure that their production methods are environmentally friendly. This approach not only benefits their clients but also contributes to the company's goal of being a responsible and sustainable manufacturer.

The Future of Resin Transfer Moulding

As industries continue to evolve, the demand for lightweight, durable, and complex composite structures will only increase. Resin Transfer Moulding is poised to play a crucial role in meeting this demand, providing manufacturers with a reliable and efficient method for producing high-performance components.

With advancements in materials and process automation, RTM will become even more accessible to a wider range of industries. Companies like us are leading the charge by embracing these innovations and continuing to push the boundaries of what is possible with Resin Transfer Moulding.

Conclusion

Resin Transfer Moulding offers a versatile, reliable, and efficient method for creating complex and durable composite structures. Its ability to produce lightweight components with high precision makes it an invaluable tool in industries such as aerospace, automotive, and construction. With companies like Datum Advanced Composites driving innovation in RTM, the future of composite manufacturing is bright, promising more advanced and sustainable solutions for the years to come.

Comments