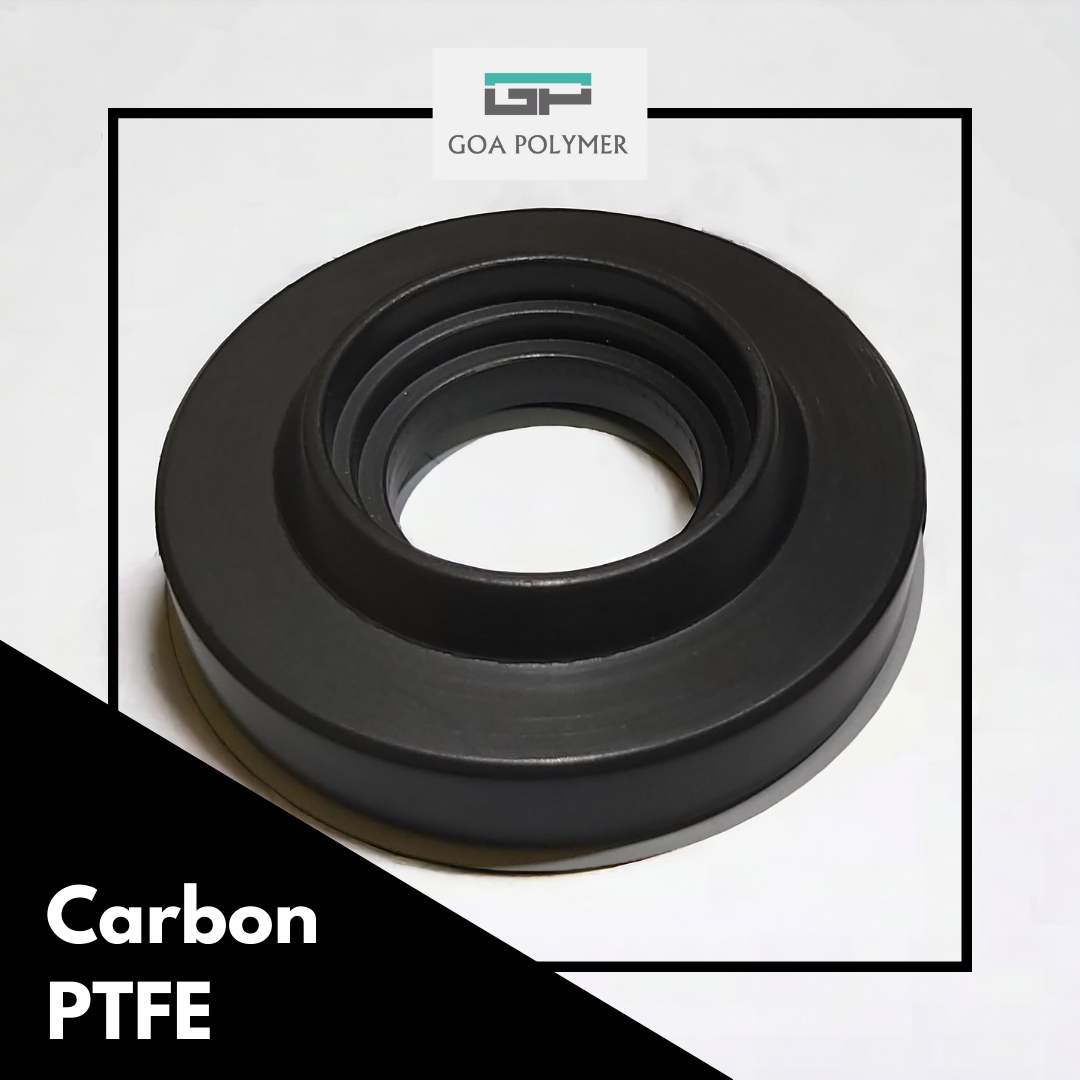

Introduction to Carbon-Filled PTFE Thrustpads

Carbon-Filled PTFE Thrustpads are an essential component of high-performance materials utilized in industrial applications. Their significance cannot be emphasized enough. These specialty parts are essential to many mechanical systems because of their remarkable endurance, resistance to wear, and decreased friction. Leading manufacturer of PTFE products Goa Polymer has been at the forefront of creating thrustpads of the highest caliber that both meet and surpass industry standards.

We will go into the world of Carbon-Filled PTFE Thrustpads in this extensive tutorial, covering its composition, uses, and advantages as well as the reasons Goa Polymer is the finest place to get these vital parts. This guide will give you the information you need whether you're an engineer, procurement professional, or just someone who wants to learn more about PTFE materials.

What is Carbon-Filled PTFE?

It's important to comprehend the substance that gives thrustpads their effectiveness before delving into their specifics: PTFE Filled with Carbon. Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer that is well-known for its non-stick qualities, low friction, and chemical resistance. Carbon filling gives PTFE better mechanical characteristics, such as better wear resistance, stronger compressive strength, and increased heat conductivity.

As it is frequently called, carbon-filled Teflon is a flexible substance that finds utility in a range of situations where conventional PTFE might not be suitable. The composite that is created when carbon is added to PTFE is called Carbon PTFE, and it is perfect for usage in thrustpads and other similar components because it is a great option for high-stress situations.

The Role of Carbon-Filled PTFE Thrustpads

In order to minimize friction between moving parts in machinery, thrustpads are essential. Pumps, compressors, turbines, and other rotating machinery frequently employ them. When carbon is added to PTFE during the thrustpad production process, there are multiple benefits.

Increased Wear Resistance: Carbon-Filled PTFE Thrustpad are made to resist the continuous abrasion that comes with operating at high speeds. By greatly increasing the wear resistance, the carbon filler prolongs the thrustpad's life.

Better Load-Bearing Capacity: The carbon addition strengthens PTFE's compressive strength, enabling the thrustpad to withstand larger loads without deforming. This holds particular significance in heavy-duty industrial settings.

Decreased Friction: The capacity of carbon-filled PTFE thrustpads to lessen friction between moving parts is one of their most important advantages. As a result, things run more smoothly and produce less heat and energy.

High Chemical Resistance: These thrustpads are appropriate for use in tough chemical environments since carbon-filled PTFE maintains the high chemical resistance qualities of pure PTFE.

Thermal Conductivity: By increasing PTFE's thermal conductivity, the carbon filler aids in the dissipation of heat produced during operation. In applications where temperatures are high, this is very advantageous.

Applications of Carbon-Filled PTFE Thrustpads

A variety of industries use carbon-filled PTFE thrustpads because of their exceptional performance qualities. Among the most popular applications are:

Thrustpads are crucial for supporting the spinning shafts and lowering friction between the moving elements of pumps and compressors. The Carbon-Filled PTFE Thrustpads from Goa Polymer are made especially to resist the challenging operating circumstances present in these applications, offering dependable performance and a longer service life.

Turbines: Carbon-Filled PTFE Thrustpads provide the requisite durability and thermal management to guarantee effective performance in turbines, where high rotational speeds generate significant heat and stress.

Automobile Industry: Thrustpads are utilized in a variety of gearboxes and transmissions, among other vehicle components. Carbon-Filled PTFE Thrustpads are perfect for these demanding applications because of their increased wear resistance and load-bearing capability.

Chemical Processing: These thrustpads can be used in chemical processing equipment because of the chemical resistance of Carbon-Filled PTFE, which allows it to tolerate exposure to harsh chemicals without deteriorating.

Aircraft Industry: Carbon-Filled PTFE Thrustpads are utilized in numerous components to ensure smooth and efficient functioning in aircraft applications, where reliability and performance are vital.

Why Choose Goa Polymer for Your Carbon-Filled PTFE Thrustpads?

Goa Polymer is a well-known brand in the industry for obtaining premium Carbon-Filled PTFE Thrustpads. This is the reason why:

Expertise and Experience: Goa Polymer has produced PTFE products for many years, and throughout that time, the company has gained a thorough grasp of the material and its uses. Because of their experience, they can guarantee that each thrustpad they make will function to the greatest possible standards.

Modern production: To create CFT Products that are dependable, long-lasting, and consistent, Goa Polymer uses state-of-the-art production techniques and technology. They will always be at the forefront of the business thanks to their dedication to innovation.

Options for Customization: Goa Polymer is aware that various applications call for various standards. To ensure that you receive a product that precisely meets your demands, they provide customization choices for their Carbon-Filled PTFE Thrustpads.

Strict Quality Control: At Goa Polymer, quality is of utmost importance. Each thrustpad is put through a rigorous inspection and testing process to make sure it satisfies the necessary requirements. This dedication to excellence guarantees that you will always receive a product that operates as promised.

Competitive Pricing: Goa Polymer's Carbon-Filled PTFE Thrustpads are reasonably priced for their superior quality, providing you with great value for your money.

Customer Support: Goa Polymer takes pride in offering exceptional customer support. Their knowledgeable team is always ready to assist you with any questions or concerns you may have, ensuring a smooth and hassle-free experience.

The Advantages of Goa Polymer’s Carbon-Filled PTFE Products

In addition to thrustpads, Goa Polymer offers a wide range of Carbon-Filled PTFE Products. These products share the same benefits as thrustpads, including enhanced wear resistance, improved load-bearing capacity, and excellent chemical resistance. Some of the most popular CFT Products offered by Goa Polymer include:

Gaskets & Seals: Carbon-Filled PTFE is a great material for gaskets and seals, offering a dependable and durable way to guarantee airtight connections and stop leaks.

Goa Polymer provides a range of carbon-filled PTFE bearings, which are perfect for applications requiring high wear resistance and minimal friction.

Bushings: In applications where traditional bushings can wear out fast, Goa Polymer's Carbon-Filled PTFE Bushings provide outstanding performance. These bushings are made to support large loads and lower friction, which guarantees smooth operation.

Carbon-filled PTFE is a material that is well-suited for valve seats due to its chemical resistance and endurance. This material ensures a tight seal and stops leaks in harsh situations.

Piston Rings: Goa Polymer's Carbon-Filled PTFE Piston Rings** are made to lower friction and create a tight seal, enhancing the effectiveness and performance of your machinery.

Maintaining and Installing Carbon-Filled PTFE Thrustpads

Maintaining and installing your Carbon-Filled PTFE Thrustpads correctly is crucial to getting the most out of them. To guarantee peak performance, consider the following advice:

Correct Installation: Verify that the thrustpad is positioned accurately and that the moving components are in line with it. Reduced performance and uneven wear might result from misalignment.

Frequent Inspection: Check the thrustpad on a regular basis for wear or damage. Prompt issue identification can assist save expensive downtime and prolong component life.

Lubrication: Although Carbon-Filled PTFE Thrustpads have low friction qualities, further lubrication could be helpful in some situations. For advice on the ideal lubricating techniques for your particular application, speak with Goa Polymer.

Temperature control: Make sure that the thrustpad's working temperature stays within the designated range. The material may deteriorate and become less effective when exposed to excessive heat.

Environmental Impact and Sustainability

Sustainability is a fundamental principle of Goa Polymer. They are dedicated to reducing the negative effects that their business and products have on the environment. Goa Polymer's carbon-filled PTFE products are made with lifespan and durability in mind, which minimizes waste and the need for frequent replacements. In addition, Goa Polymer is a good option for companies who care about the environment since they are always trying to enhance their manufacturing procedures to lower energy usage and emissions.

Conclusion: Trust Goa Polymer for the Best Carbon-Filled PTFE Thrustpads

To sum up, Carbon-Filled PTFE Thrustpad provide unparalleled wear resistance, load-bearing capacity, and friction reduction, making them a crucial part of several industrial applications. Goa Polymer is a pioneer in the business when it comes to acquiring these essential parts. They are the perfect partner for all of your PTFE product needs because of their experience, dedication to quality, and customer-focused mindset.

Comments