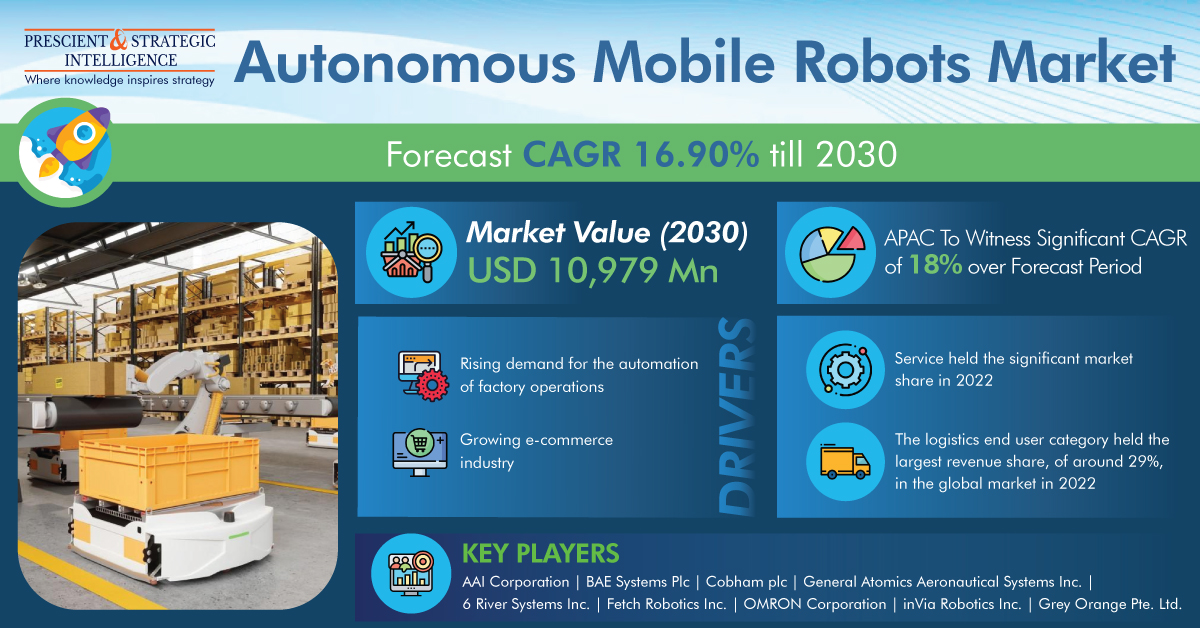

The total size of the autonomous mobile robots market was USD 3,148 million in 2022, and it will reach a value of USD 10,979 million by 2030, advancing at rate 16.90% in the years to come, as per a report by a market research company, P&S Intelligence.

The logistics category had the largest share of revenue, of about 29% in the past. These robots are chiefly installed for transportation of goods within a warehouse or storage capacity, therefore allowing actual inventory management. This results in a decrease in the complete logistics cost and streamlining supply chain.

Hence, as per the IFR, above 5 million AMRs will be functioning in about 60,000 warehouses worldwide by 2025.

Furthermore, a new breed of AMRs is assisting logistics firms with various warehouse duties. AMRs can release the humans from routine duties, letting them to lay emphasis on more-rewarding and value-adding activities.

In the years to come, a more-widespread acceptance of AMRs across a broader various use cases will be done, accompanied by progressions in their technical reliability and maturity.

The increasing requirement for factory automation solutions is a major factor driving the industry. Because of the increasing intricacies in manufacturing procedures, higher labor costs, lack of laborers, and growing emphasis on increased productivity, the requirement for factory automation solutions is increasing worldwide.

Likewise, logistical hubs and warehouses need AMRs for transportation and loading work. Additionally, in China and India, companies are more and more concentrating on automated solutions for compensating for labor shortages and advance the product quality, for competing in global markets.

APAC autonomous mobile robots market will have a significant growth rate of about 18.2% in the years to come. This will continue its dominance in the years to come. Peoples Republic, Japan, and South Korea are the key buyers of these robots, which, in line, is powering the global demand.

Moreover, because of the numerous government initiatives, for example Made in China 2025 and Make in India, which aim at accelerating automation in the manufacturing industry, the requirement for AMRs is increasing across the region, chiefly in India, Thailand, China, and Indonesia.

For example, in the Made in China 2025 plan, the government of China is applying automation and robotics technologies in the manufacturing sector.

Correspondingly, the Indian government is concentrating on formulating an ecosystem for the propagation of Industry 4.0 in each manufacturing-related sector of the nation by the 2025.

It is because of the increasing requirement for the automation of factory operations and growing e-commerce sector, the demand for autonomous mobile robots will increase significantly in the years to come.

Comments