Stainless steel sheet metal is one of the most versatile construction materials out there.

Notwithstanding the way that it is tough and sensible, it is moreover commonly easy to work with. It will in general be used in projects going from tremendous current applications to complex devices applications, and basically everything in the center.

Here's start and end you need to know about working with stainless steel in applications that require sheet metal production:

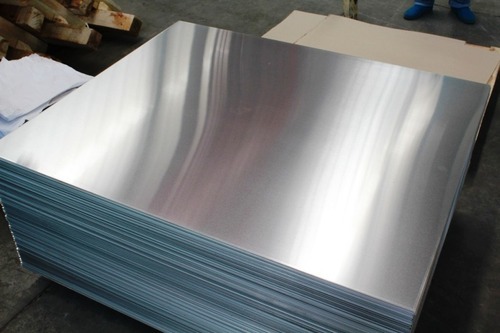

Properties of Stainless Steel 441 Sheets Metal

1. It's shimmering and outrageous.

Stainless steel is a steel combination that contains something like 10.5% chromium. The chromium content is what the future holds disintegration and antagonistic to staining properties. The real chromium content, close by the carbon content and the substance of various metals, varies considering the application where the steel will be used.

It should be seen that stainless steel isn't absolutely utilization or stain confirmation. The resistance of the metal will depend upon its substance, and certain artificial materials can hurt the metal regardless its substance. In any case, stainless offers the very best utilization and stain r esistance open, especially when you consider various attributes it offers (style, robustness, etc)

2. The sheets range in thickness up to ¼ inch.

Stainless steel sheet metal can be extremely wobbly, but for it to qualify as "sheet metal" it simply comes to a ¼ inch in thickness - - starting there ahead, the metal is suggested as "plate." The thickness of and stainless sheet metal is assessed by measure. The higher the actually look at number, the more slim the sheet.

You can reference sheet metal size charts and use an actually looking at contraption to measure your material.

3. There are a grouping of choices considering your prerequisites.

Stainless steel sheet metal shows up in a variety of plans, each with advantages and drawbacks. Makers could offer different grades, finishes and gauges, but the sorts will as a rule be standard across producers. These sorts include:

200 Series Austenitic - This series is made of chromium, carbon, manganese, or conceivably nickel. It's plausible to set this series, but one inconvenience is its shortfall of security from utilization.

300 Series Austenitic - Between the 200 series and 300 series, austenitic stainless steel makes up around 70% of all stainless steel made. The 300 series is the most flexible, weldable, and disintegration protected of all stainless steel types. The most well known grade is 304, consistently named A2 stainless. The 18% chromium content and 8% nickel content furthermore prompts 304 being suggested as 18/8.

Martensitic - This type is very astonishing and easy to machine, but it is less impenetrable to disintegration.

Ferritic - Preferred for its straightforwardness of planning, ferritic stainless is less utilization protected than austenitic.

Duplex - This promising new child around will be around 50/50 among austenitic and ferritic. It's around 2x as strong as austenitic.

Comments