Introduction:

Vibration analysis is a critical tool used in various industries to assess the condition of machinery and equipment. By measuring and analyzing vibrations, professionals can detect potential issues, identify root causes, and prevent costly breakdowns. However, the accuracy of vibration analysis is paramount to ensure reliable results and effective decision-making. In this article, we will explore the importance of accurate vibration analysis, discuss the benefits it offers, and highlight key considerations for achieving precise and actionable insights.

The Importance of Accurate Vibration Analysis:

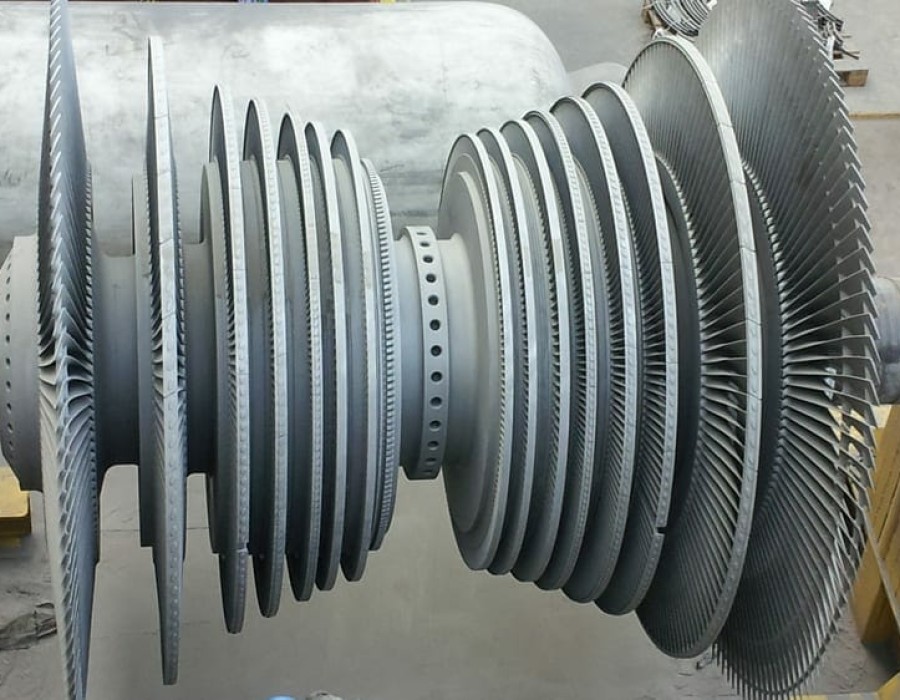

Accurate vibration analysis serves as a powerful diagnostic tool, providing valuable information about the health and performance of equipment. By accurately measuring vibrations, it becomes possible to identify mechanical imbalances, misalignments, wear and tear, and other anomalies that may lead to equipment failure or reduced efficiency. Timely detection of these issues allows for proactive maintenance and troubleshooting, preventing costly downtime, and optimizing equipment performance.

Benefits of Accurate Vibration Analysis:

a. Early Detection of Problems: Accurate vibration analysis enables the early detection of potential problems in machinery. By monitoring vibration levels over time and comparing them to baseline measurements, deviations or abnormal patterns can be identified promptly. This early warning system allows maintenance teams to intervene before issues escalate, saving time and resources.

b. Preventive Maintenance Planning: Accurate vibration analysis provides insights into the condition of equipment, facilitating data-driven preventive maintenance planning. By identifying trends and patterns in vibration data, maintenance schedules can be optimized, and necessary repairs or adjustments can be scheduled proactively. This approach minimizes the risk of unexpected failures, extends equipment lifespan, and reduces overall maintenance costs.

c. Improved Equipment Performance: By addressing underlying mechanical issues detected through accurate vibration analysis, equipment performance can be enhanced. Resolving imbalances, misalignments, or other sources of excessive vibration leads to smoother operations, reduced energy consumption, and improved productivity. This, in turn, positively impacts production output, quality, and overall operational efficiency.

Key Considerations for Accurate Vibration Analysis:

a. Reliable Equipment: To achieve accurate results, it is essential to use reliable and properly calibrated vibration analysis equipment. High-quality sensors, analyzers, and data acquisition systems ensure precise measurements and reduce the potential for inaccuracies due to equipment limitations.

b. Proper Sensor Placement: Correct sensor placement is crucial for accurate vibration analysis. Sensors should be strategically placed on equipment, considering factors such as vibration source location, machinery geometry, and expected vibration patterns. Consult equipment manuals, industry guidelines, or experienced professionals to ensure optimal sensor positioning.

c. Data Interpretation Expertise: Accurate vibration analysis goes beyond measurement; it requires expertise in data interpretation. Skilled analysts can distinguish between normal and abnormal vibration patterns, identify root causes of issues, and recommend appropriate corrective actions. Investing in knowledgeable personnel or partnering with vibration analysis specialists can enhance the accuracy and reliability of the analysis.

d. Regular Monitoring and Trend Analysis: Accurate vibration analysis is an ongoing process. Regular monitoring and trend analysis allow for the identification of changes in vibration patterns over time. Establishing baseline measurements and comparing subsequent readings helps detect subtle shifts and deviations, providing insights into the progression of equipment condition and enabling proactive maintenance strategies.

Conclusion:

Accurate vibration analysis is a valuable tool for maintaining optimal equipment performance and preventing costly failures. By conducting precise measurements, interpreting data accurately, and implementing proactive maintenance strategies, organizations can unlock insights into the health of their machinery. Early detection of issues, preventive maintenance planning, and improved equipment performance are among the key benefits that accurate vibration analysis offers. With the right equipment, proper sensor placement, skilled analysts, and a commitment to ongoing monitoring, organizations can harness the power of vibration analysis to optimize equipment reliability, increase productivity, and reduce operational costs.

For more Info :-

Comments