Stainless steel is used to identify families of steels with a minimum content of at least 11% of chromium, which is the element capable of giving the material great corrosion resistance. Stainless steels are resistant to corrosion thanks to the passivation phenomenon. The elements in stainless steel react easily with the surrounding environment, particularly the chromium. It helps to form a thin protective layer that protects the material from subsequent corrosive attacks.

Stainless steels are divided into three large families: austenitic, ferritic, and martensitic. The steels used by P5 pipe suppliers for its products belong to the family of austenitic (Series 300).

Is Aisi 316 always and in any case more resistant than Aisi 304?

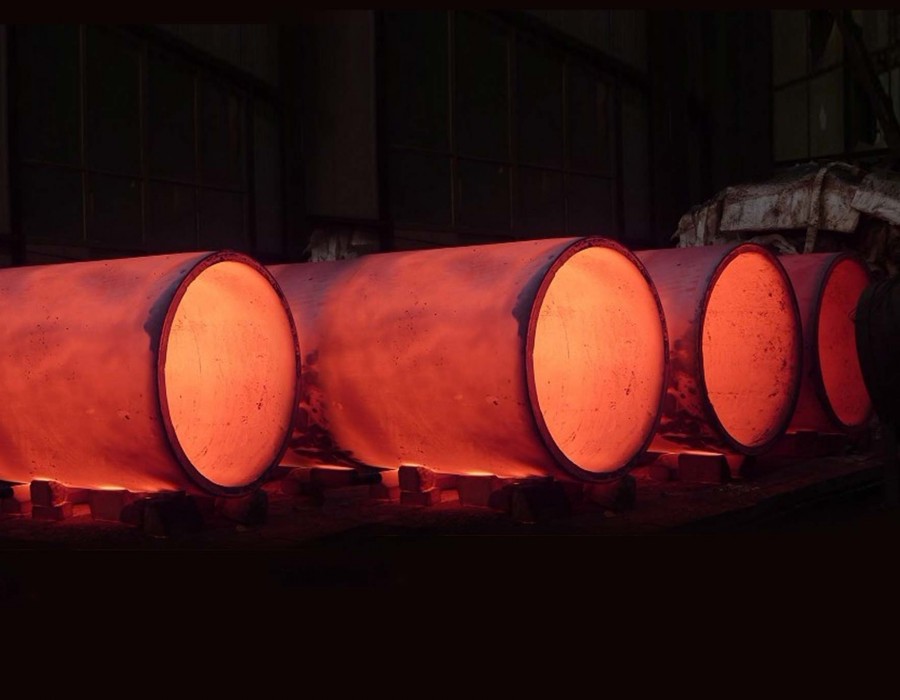

There are substances, such as nitric acid, for which 304 offers greater resistance than 316. The production techniques of stainless steel fittings vary at different p9 pipe suppliers end, and each one is indicated for the specific type of fittings. Mainly hot plastic deformation is used, bringing the material to a temperature suitable for its deformation.

For the curves, you can use the deformation method on the mandrel, which ensures the correct shape without losing the circularity of the product and without giving significant variations in thickness. Instead, they resort to hydroforming for the tees, which offers the best results, or for products particularly large for welding. On the other hand, both hot and cold forging techniques are used for end caps and reductions. The materials commonly used to make these fittings are from the austenitic steel family and AISI 316 / 316L and AISI 304 / 304L.

About AISI 316 steel

AISI 316 steel from p91 pipe suppliers is also identified by the X 5 Cr Ni 18 10. It is highly alloyed steel with high levels of chromium and nickel, which give it the characteristics of stainless steel. It is also called "18 10 stainless steel" and has always been used to create aesthetic products such as pots and cutlery sets. This is because it has excellent cold deformability, which allows it to be processed by drawing, but it also has excellent workability on machine tools.

It is particularly suitable in the food, chemical, pharmaceutical, and petrochemical sectors. It is appreciated for its good resistance to hot corrosion, which allows it to maintain good characteristics during continuous operation up to about 800 ° C.

It also has excellent resistance to the action of saline environments but optimally bears the activity of various types of acids, salts, and other chemical reagents. This makes it the ideal material for use in various fields, including the marine and food industry, where resistance to often aggressive cleaning products is required. This element gives the characteristics of resistance to corrosion by creating a superficial film of oxides.

is 3589 pipe is a non-magnetic material that is used thanks to its very high resistance in situations where an almost eternal duration is required, such as in the case of nuclear or particularly critical plants.

There is a version with the suffix L called "low carbon," characterized by lower carbon content for both abbreviations. This increases the resistance to intergranular corrosion and partially improves the weldability of these materials.

Comments