Understanding Aluminium Stucco Sheet

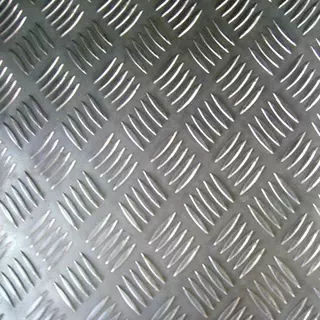

Aluminium has long been a preferred material in various industries due to its lightweight, corrosion resistance, and excellent durability. Among its many forms, Aluminium Stucco Sheet stands out as a uniquely textured variant that offers both aesthetic appeal and functional advantages. The stucco pattern, achieved through a mechanical embossing process, enhances the metal’s strength while reducing glare, making it a popular choice for construction, transportation, and decorative applications.

This type of aluminium sheet is widely used in architectural projects where both style and practicality are required. The textured surface not only provides a visually appealing finish but also improves resistance to wear and tear. Its ability to reflect light makes it suitable for insulation and roofing applications, helping to maintain energy efficiency in buildings.

Key Advantages of Aluminium Stucco Sheet

One of the primary reasons industries favor Aluminium Stucco Sheet is its durability. The embossed pattern strengthens the metal, reducing the chances of dents and scratches. This makes it an excellent choice for high-traffic areas or places exposed to physical impact. Moreover, aluminium’s natural resistance to rust and corrosion ensures that it remains in top condition even in harsh weather conditions.

Another major advantage is its lightweight nature. Compared to other metals, aluminium offers an impressive strength-to-weight ratio, making it easy to transport and install. This is particularly beneficial in large-scale industrial applications, where reducing weight can lead to significant cost savings in transportation and labor.

Additionally, its reflective properties contribute to energy efficiency. When used in insulation panels or HVAC systems, it helps in maintaining stable temperatures, reducing the need for excessive heating or cooling. This not only lowers energy consumption but also extends the lifespan of the equipment.

Aluminium Plate: Strength and Versatility

In addition to textured sheets, another widely used form of aluminium is the aluminium plate. This solid, flat sheet is known for its remarkable strength and adaptability, making it an essential material in aerospace, marine, and automotive industries. Unlike the embossed stucco variant, aluminium plates have a smooth surface, which makes them ideal for applications requiring a uniform and polished finish.

Aluminium plates are commonly used in structural applications where high tensile strength is required. They provide excellent load-bearing capacity, making them ideal for bridges, platforms, and heavy-duty machinery components. Additionally, their non-magnetic properties make them suitable for electrical applications, ensuring efficiency in power distribution systems.

The corrosion resistance of aluminium plates also makes them a preferred choice in marine environments. Saltwater exposure can be highly damaging to most metals, but aluminium’s protective oxide layer prevents deterioration, ensuring longevity and reliability in shipbuilding and offshore structures.

Applications Across Various Industries

Both Aluminium Stucco Sheet and aluminium plate have diverse applications across multiple industries. In the construction sector, aluminium stucco sheets are frequently used for roofing, wall cladding, and decorative purposes. Their ability to withstand extreme weather conditions without losing their appearance makes them an excellent choice for both residential and commercial buildings.

The transportation industry also benefits greatly from aluminium’s properties. Stucco sheets are commonly found in trailer walls, refrigeration units, and vehicle interiors, where durability and aesthetics go hand in hand. On the other hand, aluminium plates are widely used in the manufacturing of aircraft parts, truck frames, and train components due to their high strength and resistance to mechanical stress.

In the food and beverage industry, aluminium’s non-toxic and hygienic nature makes it a safe choice for storage and processing equipment. Both aluminium plates and stucco sheets are used in food processing plants, ensuring compliance with health and safety standards while maintaining efficiency in production.

Sustainability and Environmental Benefits

Aluminium is one of the most sustainable materials available today. Its recyclability plays a significant role in reducing environmental impact, as it can be reused indefinitely without losing its properties. The production of recycled aluminium requires significantly less energy compared to primary aluminium extraction, contributing to lower carbon emissions and promoting eco-friendly practices.

Both Aluminium Stucco Sheet and aluminium plate contribute to sustainable construction and manufacturing, helping industries achieve their environmental goals. By choosing aluminium-based materials, businesses not only benefit from cost savings but also support the global effort towards a greener future.

Comments