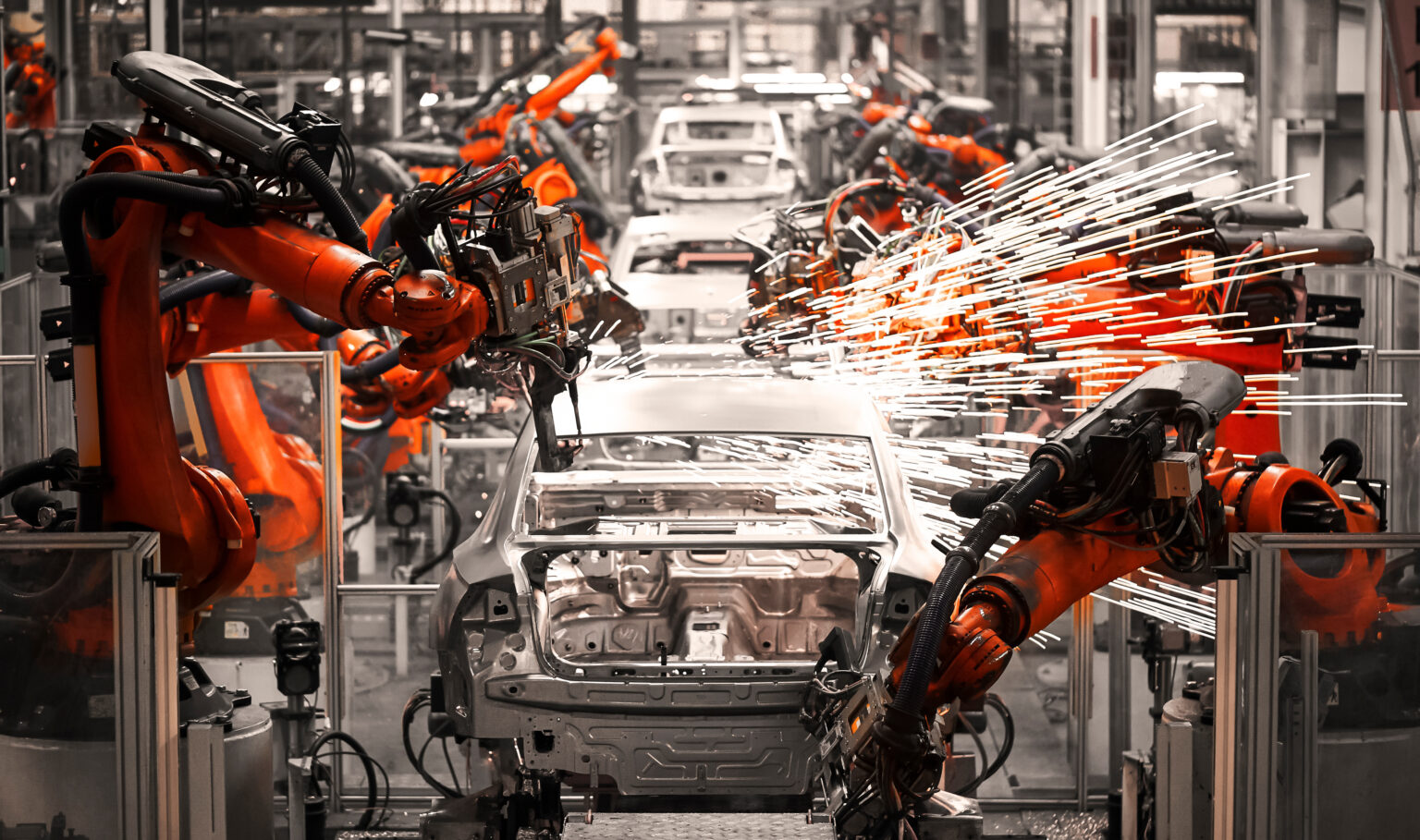

Introduction: The Shift Toward Intelligent Manufacturing

Factories once relied on clipboards and isolated machines, yet a single delayed alert can now halt an entire production line. This shift explains the growing relevance of connected systems and data driven oversight across modern plants. This article examines how managed iot solutions for the manufacturing industry address operational visibility, reliability, and scalability challenges. The central argument highlights how coordinated connectivity and monitoring transform decision making, reduce downtime, and support consistent output while aligning technology with manufacturing objectives in competitive global environments today across evolving industrial landscapes worldwide manufacturing sectors.

Strategic Importance of Managed Connectivity in Manufacturing

Understanding implementation requires examining infrastructure, security, and lifecycle management within connected factories. Decision makers increasingly consider managed iot solutions for the manufacturing industry as frameworks rather than isolated tools, especially when scaling operations. This section explains significance through reliability metrics, integration with legacy equipment, and centralized dashboards. By embedding connectivity mid paragraph, manufacturers gain timely insights, predictive maintenance capabilities, and performance benchmarks that inform planning while balancing costs, compliance, and long term modernization goals across diverse production settings in rapidly changing competitive industrial markets today globally increasingly efficiently sustainably resiliently.

Governance, Data Integrity, and Operational Alignment

Connectivity alone does not guarantee value without governance and skilled oversight. This section discusses data stewardship, vendor coordination, and operational alignment that sustain measurable outcomes. Emphasis falls on selecting interoperable platforms, defining accountability, and training staff to interpret insights responsibly. When policies support consistency, connected devices become reliable contributors to quality assurance and throughput. Effective governance also mitigates cybersecurity risks, supports regulatory expectations, and preserves continuity during expansion or restructuring, ensuring technology investments remain aligned with strategic manufacturing priorities over time across complex supply chains operations globally today continuously evolving.

Service Models Designed for Industrial Environments

Operational benefits become clearer when examining service models tailored for industrial demands. Allpoint Wireless managed iot services for manufacturing illustrate how managed connectivity, monitoring, and support converge within production environments. This section focuses on service reliability, device management, and analytics integration positioned mid paragraph. Such services help maintain uptime, streamline deployments, and coordinate responses to anomalies. The argument centers on reducing internal complexity while maintaining visibility across assets, processes, and facilities operating at scale across modern factories networks regions globally efficiently consistently securely predictably sustainably resiliently long term objectives achieved.

Continuity, Support, and Scalable Manufacturing Operations

Service continuity depends on proactive support, transparent reporting, and adaptive scaling aligned with production cycles. This section further examines Allpoint Wireless managed iot services for manufacturing by considering onboarding, diagnostics, and optimization practices. Placed in the middle of discussion, the keyword reflects integrated delivery rather than isolated features. Managed approaches allow manufacturers to focus on core competencies while service providers address connectivity health, updates, and performance trends, supporting operational confidence and informed planning during fluctuating demand cycles markets conditions globally today efficiently reliably securely consistently sustainably resiliently at scale enterprise.

Measuring Performance and Enabling Continuous Improvement

Manufacturing leaders increasingly evaluate outcomes through metrics such as yield, downtime, and energy efficiency. This section analyzes how connected intelligence supports continuous improvement initiatives without disrupting workflows. Emphasis remains on interoperability, incremental deployment, and evidence based evaluation. By aligning data streams with operational goals, organizations can identify bottlenecks and validate improvements. The broader significance lies in creating adaptable systems that evolve with product lines, regulations, and market pressures over extended operational lifecycles within competitive industrial sectors globally today efficiently resiliently sustainably strategically responsibly predictably consistently securely long term value creation.

Evaluating Partners and Ensuring Long Term Fit

Selecting partners requires assessing experience, transparency, and long term support commitments. This section outlines evaluation considerations relevant to industrial connectivity initiatives, including service level clarity and responsiveness. Attention also turns to change management and stakeholder communication that influence adoption success. When expectations align, connected programs integrate smoothly into existing operations. The discussion reinforces the importance of neutrality, data integrity, and continuity, ensuring technology initiatives complement manufacturing culture rather than disrupt established processes across diverse organizations facilities regions globally today consistently ethically sustainably strategically responsibly efficiently resiliently over time periods ahead.

Conclusion: Connectivity as a Foundation for Modern Manufacturing

Industrial connectivity continues reshaping production strategies through measured, service oriented approaches. This conclusion reiterates the article’s main argument that managed connectivity enables reliability, insight, and scalability when aligned with operational goals. Allpoint Wireless represents a provider operating within this evolving landscape. With informed planning and neutral assessment, manufacturers can pursue connected initiatives that support resilience, efficiency, and sustained competitiveness in demanding global markets across modern industries sectors facilities networks supply chains worldwide today continuously evolving strategically responsibly sustainably forward.

Comments