Drum handling equipment uk is an essential part of many industrial and manufacturing operations in the UK, as it allows for the safe and efficient movement of drums filled with liquids, solids, or gases. These drums can be heavy and awkward to handle, so the use of specialized equipment can help reduce the risk of accidents and injuries to workers.

There are several types of drum handling equipment available, each designed to suit different needs and applications. Some of the most commonly used types of equipment include:

Drum Handlers: These are mechanical devices that are used to lift and move drums from one location to another. There are several types of drum handlers available, including forklift attachments, hand-held units, and electric hoists.

Drum Crushers: These are specialized machines that are used to compress empty drums to reduce their volume, making them easier to store and transport. Drum crushers can also be used to safely puncture and drain the contents of drums that are no longer needed.

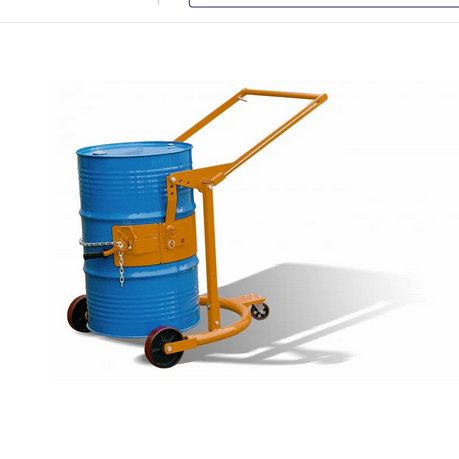

Drum Dollies: These are simple, portable platforms that are used to move drums around a facility. They can be equipped with casters or wheels to make them easier to maneuver, and many models also have built-in handles or grips to allow for manual handling.

Drum Racks and Storage Systems: These are designed to securely store and organize drums within a facility. Drum racks can be freestanding or mounted to a wall, and they may be made of metal, plastic, or other materials. Some storage systems are also equipped with spill containment features to help prevent accidents.

Drum Handling Accessories: There are also a number of accessories available to help with the handling and storage of drums, including drum faucets, plugs, and seals. These can help prevent spills and leaks, and can also be used to dispense the contents of a drum in a controlled manner.

Safety is a key concern when it comes to drum handling, as accidents can result in serious injuries or even fatalities. It is important to follow proper procedures and use the appropriate equipment to ensure that drums are handled safely. This includes using the correct lifting techniques, wearing protective gear, and inspecting equipment regularly to ensure that it is in good working order.

There are several factors to consider when choosing drum handling equipment, including the size and weight of the drums being handled, the type of material they contain, and the specific handling needs of the facility. It is also important to consider the available budget and the expected lifespan of the equipment.

There are many companies in the UK that offer drum handling equipment, and it is important to do some research and compare different options before making a purchase. It may also be helpful to seek the advice of a professional to ensure that the right equipment is selected for the specific needs of the facility.

Overall, drum handling equipment is an essential part of many industrial and manufacturing operations in the UK, and it is important to choose the right equipment and follow proper procedures to ensure the safe and efficient handling of drums. By doing so, companies can help prevent accidents and injuries, and can also improve the efficiency of their operations.

Comments